Cut Resistant Gloves Manufacturer

Cut Resistant Gloves Factory

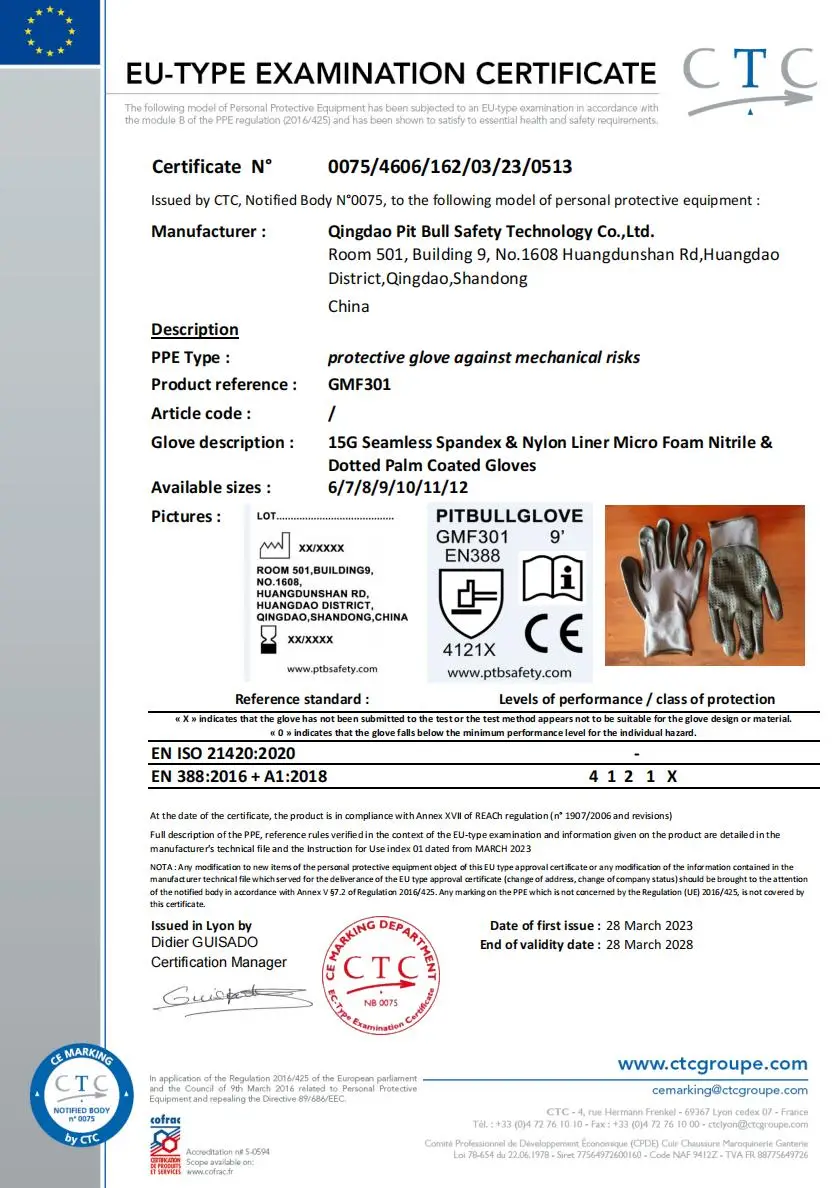

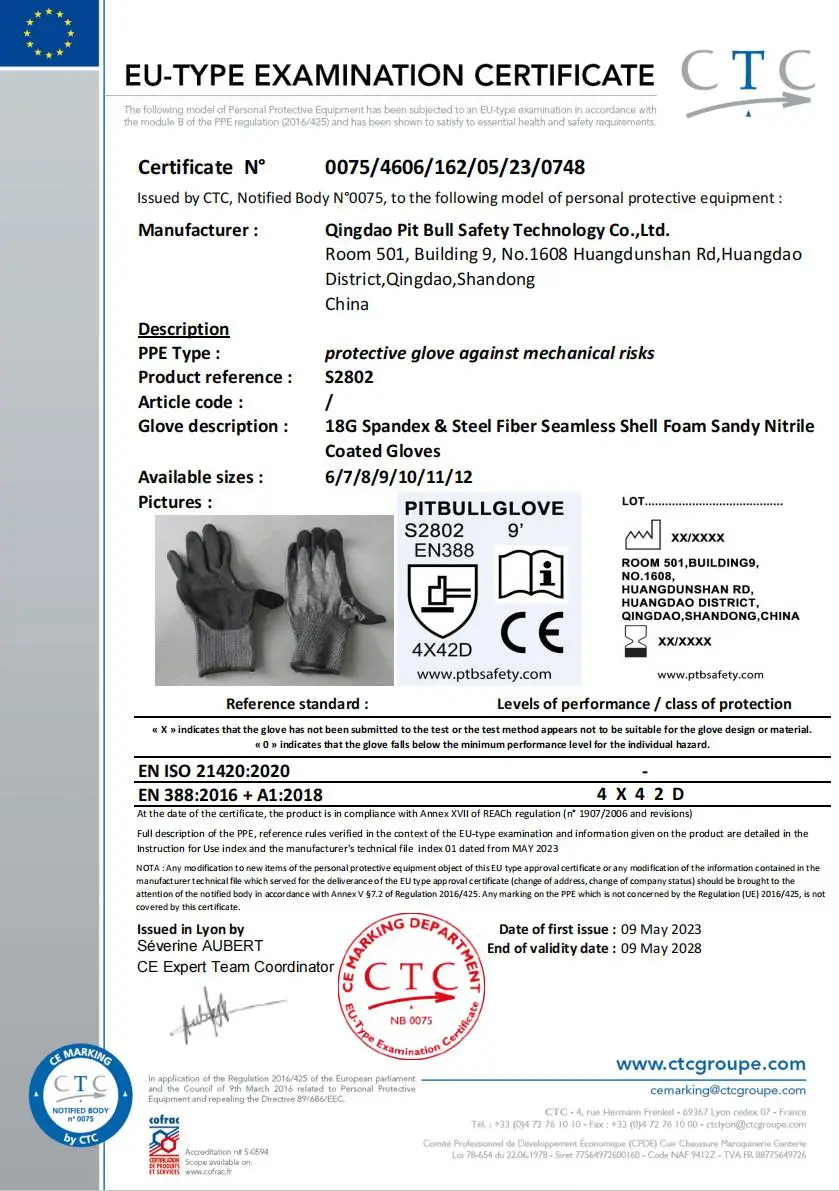

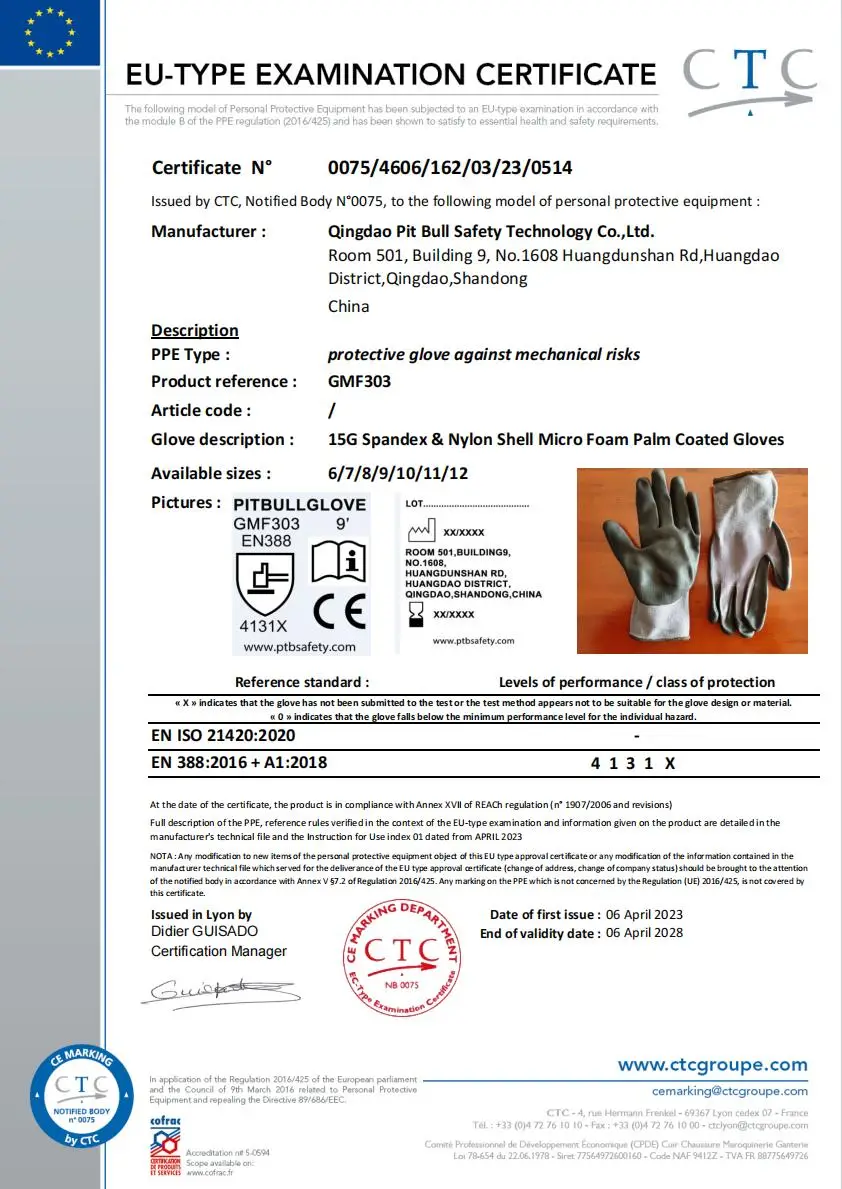

ISO9001, CE, ANSI Approval

ISO9001 & Oeko-Tex Certified

Quality management systems & safe materials

EN 388 / ANSI Cut Levels

Meeting the highest international standards

Flexible OEM/ODM Specialist

Customized to your exact specifications

Competitive Pricing

Optimized for wholesalers and bulk orders

Superior Cut Protection

Graphene’s exceptional strength provides unmatched cut resistance, ensuring worker safety in hazardous tasks.

Lightweight and Comfortable

Unlike traditional heavy gloves, graphene gloves are lightweight, offering comfort and reducing hand fatigue during long hours of use.

Durability and Cost Efficiency

The toughness of graphene ensures a longer lifespan, making these gloves a cost-effective solution for industrial use.

Your Trusted Cut & Impact Resistant Gloves Manufacturing Partner

Looking for a reliable supplier to meet your graphene cut resistant glove manufacturing needs with quick turnaround times? BullSafety is a leading manufacturer of high-performance graphene cut resistant gloves, specializing in both standard and custom-made solutions for a wide range of industries, including construction, manufacturing, and more.

We offer an extensive selection of graphene gloves, tailored to meet your specific needs, including different sizes, materials, and designs. Our ISO 9001 certified production process, paired with our in-depth expertise and advanced manufacturing technology, ensures that your products are produced with precision and consistency, every time.

PU Cut Resistant Gloves

ANSI A4/EN388 Level D Cut Resistance

Highest industry rating for protection against cuts and lacerations

Excellent Dexterity & Tactile & Sensitivity

Lightweight PU

Good Dry Grip

Suitable for precise tasks in dry conditions.

Lightweight & Comfortable

Easy to wear.

Application Industries

Electronics Assembly, Precision Instruments, Quality Inspection, Aerospace, Small Parts Handling,

MOQ: 6000 pairs

Avaliable Size : S-2XL

Nitrile Cut Resistant Gloves

ANSI A3-A7 /EN388 Level A-F Cut Resistance

Highest industry rating for protection against cuts and lacerations

Excellent Wet & Oily Grip

Sandy nitrile coating excels in oily and wet environments

Good Abrasion & Oil Resistance

Nitrile coating is durable and withstands oils.s

Well-Balanced

Offers a good mix of protection, grip, and durability.

Application Industries

Automotive Manufacturing & Repair, Sheet Metal Fabrication, Glass Handling & Installation, Construction, Logistics & Warehousing, Equipment Maintenance

MOQ: 6000 pairs

Avaliable Size : S-2XL

Graphene Cut Resistant Gloves

ANSI A3-A7 /EN388 Level A-F Cut Resistance

Highest industry rating for protection against cuts and lacerations

Excellent Breathability & Comfort

Foam coating structure offers superior breathability for extended wear.

Good Dry & Light Oil Grip

Provides reliable grip, especially on dry and slightly oily surfaces

High Dexterity & Tactility

Coating is typically thin, allowing good flexibility.

Application Industries

Repetitive assembly tasks, Handling parts with light oil residue, General equipment upkeep and maintenance, Handling cardboard boxes, packages

MOQ: 6000 pairs

Avaliable Size : S-2XL

Impact & Cut Resistant Gloves

ANSI A3-A7 /EN388 Level A-F Cut Resistance

Highest industry rating for protection against cuts and lacerations

Triple Protection

Offers cut resistance, impact resistance (back TPR protection) , and anti-slip grip.

Excellent Wet & Oily Grip

Sandy nitrile coating provides superior grip in oily and wet conditions.

Abrasion Resistant & Durable

Coating and liner are built for durability

Good Oil Resistance

:Nitrile material resists oils.

Application Industries

Oil & Gas, Heavy Construction, Mining, Heavy Machinery Operation & Repair, Demolition, Heavy Automotive

MOQ: 6000 pairs

Avaliable Size : S-2XL

PU Cut Resistant Gloves

PU620

13 gauge A4 & cut D gloves

PU640

13 gauge A4 & cut D gloves

PU650

13 gauge A5 & cut E gloves

PU1506

13 gauge A3 & cut C gloves

PU1601

15 gauge A4 & cut D gloves

PU640

18 gauge A3 & cut C gloves

PU2906

18 gauge A5 & cut E gloves

PU2803

18 gauge A4 & cut D gloves

PU2807

13 gauge A4 & cut D gloves

PU3903

21 gauge A4 & cut D gloves

Nitrile Cut Resistant Gloves

GS430

13 gauge A4 & cut D sandy nitrile gloves

GAS510

13 gauge A5 & cut E sandy nitrile gloves

GMF237

15 gauge A3 & cut C microfoam gloves

GMF300

13 gauge A4 & cut D sandy nitrile gloves

PU1601

15 gauge A4 & cut D double nitrile gloves

PU640

13 gauge A4 & cut D double nitrile gloves

GMF2613

18 gauge A2 & cut B microfoam gloves

MFH2613

18 gauge A2 & cut B microfoam gloves

S2901

15 gauge A6 & cut F sandy nitrile gloves

F3101

18 gauge A6 & cut F foam nitrile gloves

Graphene Cut Resistant Gloves

GRS2112

13 gauge A9 sandy nitrile gloves

GRMF2313

15 gauge A3 & cut C microfoam gloves

GRS2412

15 gauge A4 & cut D sandy nitrile gloves

GRS2512

15 gauge A5 & cut E double nitrile gloves

GRF2707

18 gauge A3 & cut C foam nitrile gloves

GRS2803

18 gauge A4 & cut D sandy nitrile gloves

GRPU2807

18 gauge A4 & cut D PU gloves

GRS3107

18 gauge A6 & cut F microfoam gloves

GRPU3607

21 gauge A3 & cut C PU gloves

GRS3707

21 gauge A4 & cut D sandy nitrile gloves

Impact Cut Resistant Gloves

GFP0812

13 gauge A9 sandy nitrile gloves

GP0412

15 gauge A3 & cut C microfoam gloves

GP1501

13 gauge A3 &cut C sandy nitrile impact cut resistant gloves

GP1601

13 gauge A4 & cut D PU impact cut resistant gloves

GP1606

13 gauge A4 & cut D sandy nitrile impact cut resistant gloves

GP1608

13 gauge A4 & cut D sandy nitrile impact cut resistant gloves

GP2502

18 gauge A4 & cut D PU gloves

GP2902

18 gauge A5 & cut E microfoam gloves

GP3607

21 gauge A3 & cut C PU gloves

GP3707

21 gauge A4 & cut D sandy nitrile gloves

What can BullSafety customise for you?

Three reasons to choose Bullsafety as your reliable cut resistant gloves supplier

Knitting Counts

Gloves liner are available in 10, 13, 15, 18, and 21 gauge. This variety ensures flexibility and durability. Each count meets different work environment needs, providing reliable performance for various tasks.

Cut Resistance

Levels from European Cut A to Cut F and United States ANSI A1 to A9 are provided. These standards ensure necessary protection. Customers can choose the appropriate level based on their safety requirements.

Color

BullSafety provide customizable dipping and liner colors to suit your preferences and requirements, giving you the flexibility to tailor the gloves to your unique specifications.

Simplify Your Custom Cut Resistant Gloves Production Process with BullSafety

At BullSafety, we’ve made the customization of your hand protection solutions as easy as possible. Our seamless, four-step process ensures that you receive full support throughout the journey of creating your custom gloves, from design to production.

Specify Application

Clearly outline the purpose your gloves will serve. Whether it’s for heavy-duty work, high dexterity tasks, or protection from specific hazards, our team will ensure the design fits your needs exactly.

Define Usage Needs

Share the details of your working environment. Includes temperature, exposure to chemicals, abrasion levels, and overall hand safety requirements. We’ll ensure the materials are perfectly suited to meet the your demands.

Select Protection Features

Choose the protection levels that best suit your needs. From cut-resistant properties to enhanced grip and comfort, we can integrate the right features for maximum safety and performance.

Finalizing Design & Specifications

Submit your designs, dimensions, and preferences. We’ll refine the specifications and ensure your gloves are manufactured to your exact requirements, ensuring they perform just as you envisioned.

Why Partner with BullSafety for Cut Protection?

Proven Expertise & Innovation

Founded by William Chen, a seasoned glove protection researcher with expertise in material science and ergonomic design for safety and comfort.

Quality Assurance You Can Trust

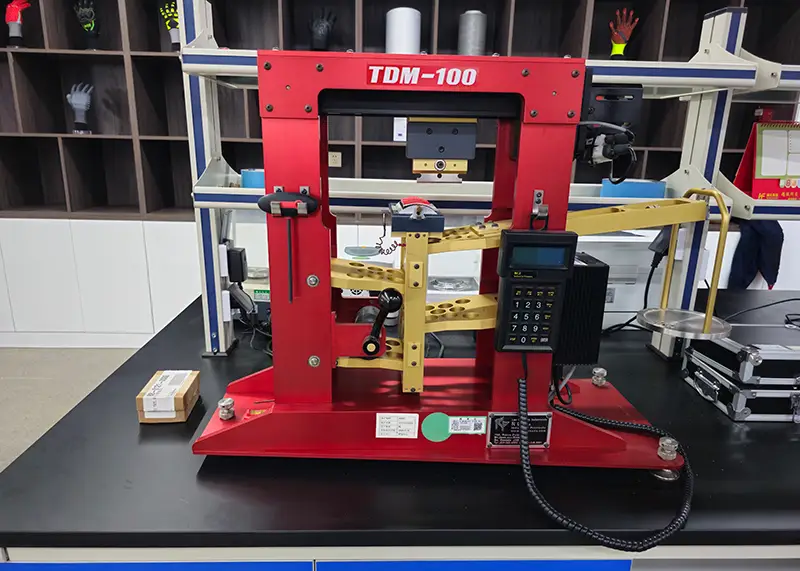

ISO 9001 certified processes, Oeko-Tex Standard 100 materials, and rigorous batch testing ensure consistent quality with every order.

Commitment to Partnership & Support

Dedicated support for wholesalers, technical advice on materials/standards, and a focus on building long-term relationships.

Sustainability Focus

Use of responsible materials, commitment to environmental practices, and continuous improvement in sustainability initiatives.

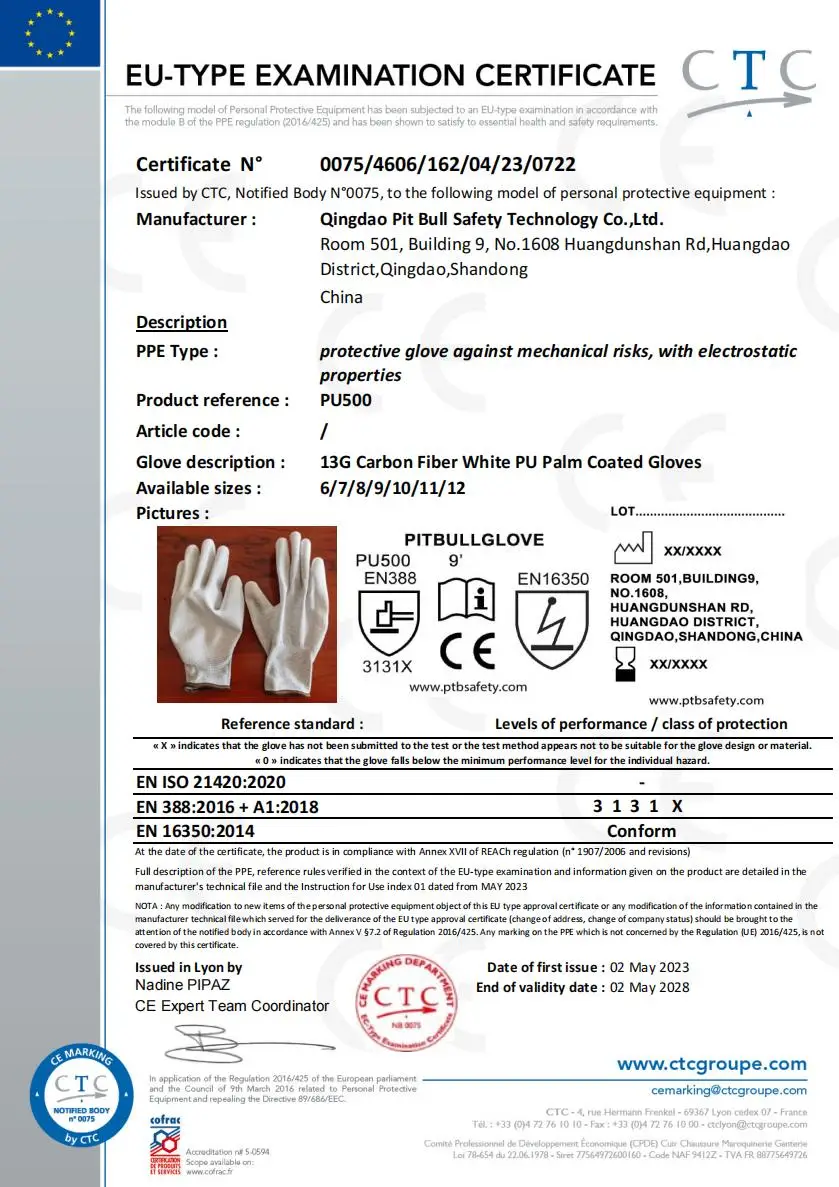

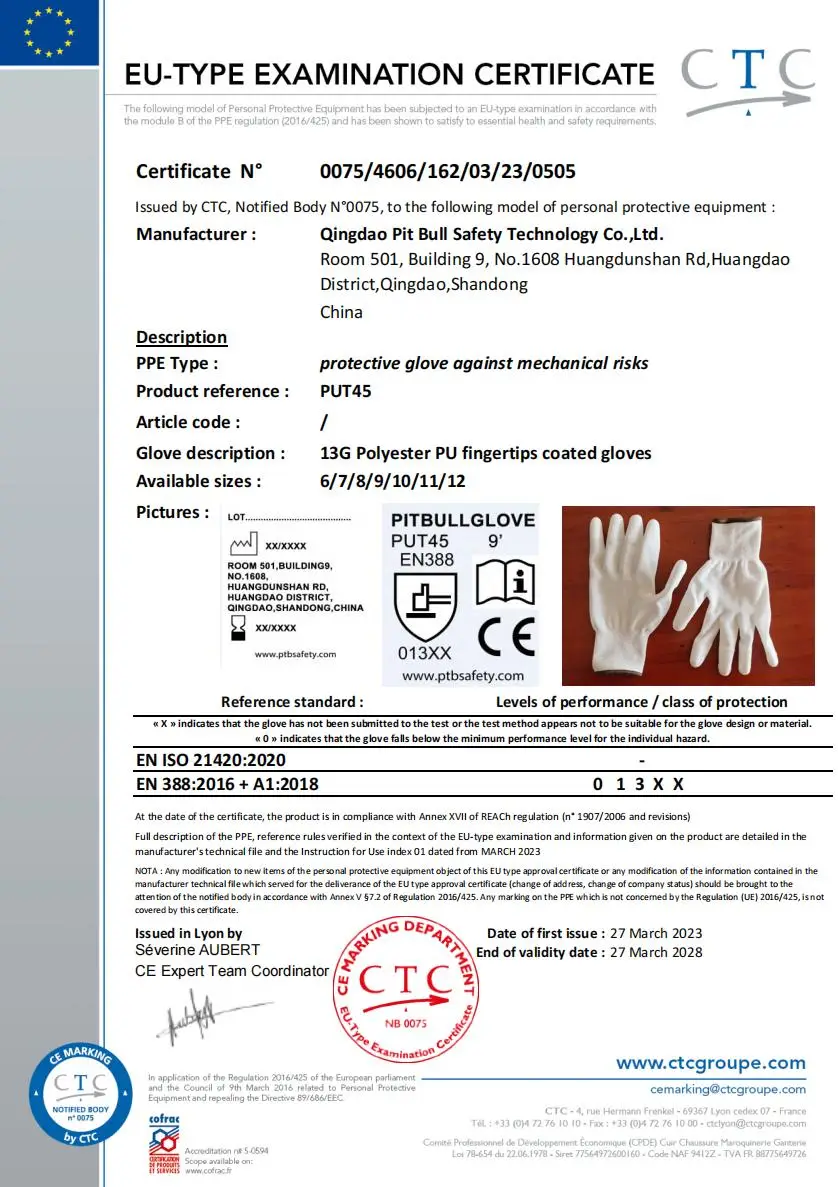

CERTIFICATE

Trusted by PPE Wholesalers Worldwide

"Working with BullSafety has been brilliant. Their gloves consistently meet those strict European standards – no problem there – and deliveries are rock solid, always on schedule. William, Cathy and her team really get what we need; they feel more like partners than just suppliers."

Mr. Jason Kim, Purchasing Manager Linkedin

"BullSafety really helps us stand out because they customize stuff so well and always have fresh ideas. This market's tough, right? We need unique products, and BullSafety nails it. They make gloves exactly how we need them (hitting ANSI standards), plus they actually help with design and materials, bringing cool ideas to the table. And the best part? Their prices are great, but the quality and innovation are still top-notch. They're super easy to work with, respond fast, and have made buying from them way simpler."

— Ms. Emily Stenning, Product Manager Tweet

"Basically, BullSafety's awesome. Great gloves, they care about being green – which matters to us and our customers now, helps us get deals. And their service? Top-notch. Fixed a problem fast. Good stuff, good price, eco-friendly, great support. Definitely the right move."

KARLA MAYORQUIN, General Manager Facebook

Here are 10 frequently asked questions (FAQ) about graphene gloves

What are graphene gloves made of?

Graphene gloves are typically made by incorporating graphene, a single layer of carbon atoms, into the fabric or coating of the gloves. This makes the gloves lightweight, durable, and highly conductive.

What are the benefits of graphene gloves

Graphene gloves offer numerous benefits, including increased strength, improved flexibility, enhanced touch sensitivity, and better resistance to wear and tear. They also have excellent thermal and electrical conductivity.

Are graphene gloves cut-resistant?

Yes, graphene gloves are often designed with cut-resistant properties. Graphene’s strength and flexibility help make the gloves resistant to cuts and abrasions, providing extra protection in high-risk environments.

How do graphene gloves compare to traditional work gloves?

Compared to traditional work gloves, graphene gloves are typically lighter, more durable, and offer superior flexibility. They also provide enhanced breathability and comfort, while maintaining a high level of protection.

Can graphene gloves protect against extreme temperatures?

Yes, graphene has excellent thermal conductivity properties, making graphene gloves effective in both hot and cold environments. They can help regulate temperature, keeping your hands cooler in hot conditions and warmer in cold conditions.

Are graphene gloves waterproof?

While graphene itself is not inherently waterproof, many graphene gloves are treated with additional coatings or materials that make them water-resistant or waterproof, depending on the design.

Do graphene gloves provide good grip?

Yes, graphene gloves offer excellent grip due to their high friction surface, making them ideal for tasks that require precision, such as handling small parts or tools.

How durable are graphene gloves?

Graphene gloves are highly durable, thanks to the inherent strength of graphene. They resist wear and tear better than many traditional gloves, and can last longer under heavy use, especially in demanding environments.

Are graphene gloves suitable for all industries?

Graphene gloves are suitable for a wide range of industries, including manufacturing, construction, automotive, electronics, and healthcare. Their versatility makes them ideal for environments that require both dexterity and protection.

Can graphene gloves be customized with a logo or design?

Yes, Bullsafety offer customization options for graphene gloves. You can add logos, brand names, or specific designs to suit your company’s needs.

Get Your Custom Quote for Cut Resistant Gloves

Discuss your specific requirements (cut level, materials, quantity, customization) with our specialists. Let us be your reliable manufacturing partner.