What is the EN 388 Standard?

The EN 388 standard is one of the most important criteria when selecting protective gloves for workers exposed to mechanical hazards. It is designed to ensure that gloves can withstand the demands of different tasks, from handling sharp objects to protecting against abrasions.

The EN 388 standard evaluates gloves on their ability to resist mechanical risks such as abrasion, cutting, tearing, and puncture. These factors are crucial in ensuring the safety and comfort of workers in hazardous environments.

If you’re sourcing gloves for industrial applications, understanding what the EN 388 standard entails can help you select the best products. Let’s break it down further and understand how it impacts glove performance and safety.

What is the EN 388 standard on hand protection?

The EN 388 standard is vital when assessing the quality and safety of gloves intended for mechanical protection. But how exactly does it help ensure that gloves meet the necessary safety criteria?

EN 388 defines how gloves perform against risks such as abrasion, cutting, tearing, and puncture, making it easier to determine the right gloves for various industrial tasks.

The EN 388 standard applies a series of tests to evaluate the protective performance of gloves under mechanical stress. Each test measures a different aspect of the glove’s ability to resist physical damage. This includes the following four core tests:

Abrasion Resistance (EN 388 Abrasion Test)

The abrasion resistance test measures the number of cycles a glove can withstand when rubbed against a rotating abrasive surface. It is conducted using a rotary drum and the glove material is subjected to sandpaper or another abrasive surface. A higher number of cycles means a more durable glove. The test results are graded from 1 to 4, with 4 being the best performance.

Cut Resistance (ISO 13997 / Coup Test)

This test measures how well a glove resists cutting. In the Coup Test (part of the EN 388 standard), a rotating circular blade is used to cut through the glove. The number of cycles it takes for the blade to cut through the glove is measured. A higher number of cycles indicates better cut resistance.

Tear Resistance (EN 388 Tear Test)

This test evaluates how much force is needed to tear a glove. A sample of the glove is placed between two jaws, and the force required to tear it is measured. The higher the resistance, the better the glove will protect workers from tearing when exposed to stress or impact.

Puncture Resistance (EN 388 Puncture Test)

The puncture resistance test measures the force required to puncture the glove with a standard probe. This is particularly important in environments where workers may be exposed to sharp objects or materials that could penetrate the glove. The results are graded from 1 to 4.

EN 388 Scoring System:

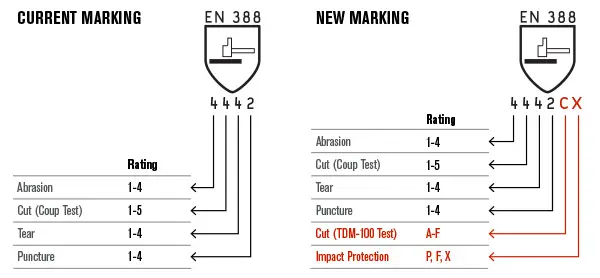

The results of these tests are used to assign a score to the gloves. The score is represented by a four-digit number, each representing the glove’s performance in the four tests:

| Abrasion Resistance | Cut Resistance | Tear Resistance | Puncture Resistance |

|---|---|---|---|

| 1-4 (1 = low, 4 = high) | 1-5 (1 = low, 5 = high) | 1-4 (1 = low, 4 = high) | 1-4 (1 = low, 4 = high) |

Example:

A glove with a rating of 4X43F would indicate the following:

- 4: Excellent abrasion resistance

- X: Not tested for cut resistance (in some cases, a letter ‘X’ means the test was not applicable or failed)

- 4: Good tear resistance

- 3: Moderate puncture resistance

- F: Cut resistance (using ISO 13997) rating of 1 to 5 (F = the lowest score for cut resistance)

How to test the gloves based on EN388 standard?

Testing gloves based on the EN 388 standard involves a series of mechanical resistance tests. But how exactly are these tests carried out and what do they tell us about a glove’s performance?

Gloves are tested under EN 388 using a combination of rotary and mechanical tests to assess their ability to resist abrasion, cutting, tearing, and puncturing. These tests help ensure gloves meet the highest safety standards.

The testing process for gloves under EN 388 is quite thorough and requires specialized equipment. Here’s a deeper look at each test and the equipment used:

Abrasion Test

The abrasion resistance test involves rubbing the glove against an abrasive surface, usually sandpaper, to simulate wear and tear. The glove’s ability to withstand this friction is scored by how many cycles it takes before it is worn through. Gloves that score 4 (indicating high abrasion resistance) can withstand over 8,000 cycles, while a score of 1 indicates just 100 cycles.

Cut Resistance Test (Coup Test)

The Coup Test uses a rotating circular blade to cut through the glove. The blade is pressed down onto the glove, and the number of rotations it takes to cut through is recorded. The more rotations it takes to cut through, the better the glove’s cut resistance.

Puncture Resistance Test

This test uses a standardized probe to apply force to the glove. The amount of force required to puncture the glove is measured, which indicates how much protection the glove offers against sharp objects. The higher the score, the better the glove is at resisting punctures.

Tear Resistance Test

The tear resistance test is done by pulling a glove material apart to measure how much force is needed to cause a tear. A glove with high tear resistance can withstand rough handling without breaking.

Testing Equipment:

- Rotating drum for abrasion tests

- Rotating blade for cut resistance tests

- Puncture probe for puncture resistance

- Tensile testing machine for tear resistance

What is ISO 13997?

ISO 13997 is an important part of the EN 388 standard, especially when assessing a glove’s cut resistance. But how does it differ from traditional cut tests?

ISO 13997 focuses on measuring the force required to cut through a glove, giving a more precise and standardized measure of cut resistance compared to the Coup test.

ISO 13997, also known as the “Blade Cut Test,” is widely used for measuring the cut resistance of gloves. Unlike the Coup Test, which measures how many rotations it takes to cut through the glove, ISO 13997 measures the actual force applied during the cutting process.

The Test Process:

The glove is placed under a rotating blade, and a defined amount of pressure is applied. The force needed to cut through the glove is measured in Newtons (N). The higher the number of Newtons, the more resistant the glove is to cuts.

Key Differences Between ISO 13997 and Coup Test:

- ISO 13997 uses a constant pressure to measure the actual force required to cut through the glove.

- Coup Test measures the number of rotations it takes to cut through the glove, which can be less precise.

ISO 13997 Scoring:

The score is represented by a letter, ranging from A (the lowest level of protection) to F (the highest level of protection):

| Score | Force (N) |

|---|---|

| A | 2-5 |

| B | 5-10 |

| C | 10-15 |

| D | 15-22 |

| E | 22-30 |

| F | 30+ |

A glove rated as F in ISO 13997 offers the highest protection against cuts.

What is the difference between cut resistance test and ISO 13997 test?

While both the cut resistance test and ISO 13997 assess cut protection, they differ in methodology and precision. Let’s explore these differences.

The key difference between traditional cut resistance testing and ISO 13997 lies in how the tests are conducted—ISO 13997 uses a standardized force measurement, while the traditional test relies on rotations to measure resistance.

Understanding the difference between traditional cut resistance tests and ISO 13997 is crucial when sourcing gloves for applications where cut protection is paramount.

Traditional Cut Resistance Test:

In the traditional cut resistance test, the glove material is subjected to a rotating blade that moves back and forth. The number of rotations before the blade cuts through the material indicates its resistance. This test is useful but can be less consistent because it doesn’t measure the exact force used.

ISO 13997 Cut Resistance Test:

ISO 13997 measures the force applied to the glove using a rotating blade. The force required to cut through the material is quantified in Newtons. The scoring system (A-F) gives a precise understanding of the glove’s cut resistance, making it more reliable and standardized.

Comparison Table: Traditional Cut Resistance vs. ISO 13997

| Feature | Traditional Cut Resistance Test | ISO 13997 Test |

|---|---|---|

| Methodology | Rotations to cut through the glove | Force measured in Newtons |

| Scoring System | Less precise | Precise, A-F scale |

| Focus | Number of rotations | Exact force required |

| Precision | Lower | Higher |

======================================================================================================================

10 Frequently Asked Questions (FAQs) about EN388,the European standard for protective gloves against mechanical risks:

1. What is EN388?

EN388 is a European standard (EN 388:2016+A1:2019) that specifies performance requirements and testing methods for protective gloves against mechanical risks. It assesses gloves’ resistance to abrasion, cutting, tearing, and puncture, ensuring they provide adequate protection in various industrial applications.

2. Why is EN388 certification important?

EN388 certification ensures that protective gloves meet specific safety standards for mechanical hazards. It helps employers select appropriate gloves to protect workers from risks like abrasion, cuts, tears, and punctures, thereby enhancing workplace safety and compliance with European regulations.

3. What are the main test categories in EN388?

EN388 evaluates gloves based on four primary mechanical properties:

- Abrasion Resistance (scale 1-4)

- Cut Resistance (scale 1-5)

- Tear Resistance (scale 1-4)

- Puncture Resistance (scale 1-4)

Each category is rated numerically, with higher numbers indicating greater resistance.

4. How is the EN388 rating system structured?

The EN388 rating consists of four digits corresponding to the four test categories:

- First Digit: Abrasion resistance (1-4)

- Second Digit: Cut resistance (1-5)

- Third Digit: Tear resistance (1-4)

- Fourth Digit: Puncture resistance (1-4)

For example, a glove rated EN388 4321 has:

- Abrasion resistance: 4

- Cut resistance: 3

- Tear resistance: 2

- Puncture resistance: 1

5. What materials are commonly used in EN388 certified gloves?

EN388 certified gloves are made from various materials, each offering different levels of protection:

- Leather: High abrasion and tear resistance

- Kevlar® or Aramid Fibers: Excellent cut and puncture resistance

- Nitrile or Latex: Good flexibility and puncture resistance

- Polyester or Nylon: Durable and abrasion-resistant

- Rubber: Provides puncture and tear resistance

6. Can a glove have different EN388 ratings for different areas?

Yes, gloves can have varied EN388 ratings in different sections to provide tailored protection. For example, the palm area might have a higher abrasion resistance rating, while the back of the hand might prioritize flexibility. This design ensures optimal protection where it’s most needed without compromising comfort.

7. How often should EN388 certified gloves be inspected or replaced?

Gloves should be regularly inspected for signs of wear, damage, or reduced protective qualities. The frequency depends on usage intensity and environmental conditions but generally:

- Daily Inspections: For visible damage or wear

- Periodic Replacements: Based on manufacturer recommendations or after significant exposure to hazards

Always replace gloves that no longer meet the required EN388 standards to maintain safety.

8. Are EN388 gloves suitable for all industries?

While EN388 gloves are designed for protection against mechanical risks, their suitability varies by industry:

- Construction: High abrasion and cut resistance

- Automotive: Tear and puncture resistance

- Metalworking: Puncture and cut resistance

- Logistics and Warehousing: General abrasion and tear protection

It’s essential to select gloves with appropriate EN388 ratings based on specific industry hazards.

9. How does EN388 differ from other glove standards like ANSI or ASTM?

EN388 is a European standard focusing on mechanical risks with a specific rating system. In contrast:

- ANSI/ISEA 105: A North American standard that classifies gloves based on cut, puncture, abrasion, and other hazards with separate ratings.

- ASTM Standards: Various ASTM standards cover different aspects of glove performance, including chemical resistance and thermal protection.

While both EN388 and ANSI/ISEA 105 assess mechanical protection, their testing methods and rating systems differ, reflecting regional safety requirements.

10. Where can I find EN388 certified gloves?

EN388 certified gloves are available through:

- Safety Equipment Suppliers: Specialized retailers often carry a wide range of certified gloves.

- Online Marketplaces: Websites like Amazon, Grainger, or specific industrial suppliers.

- Manufacturer Websites: Brands like Ansell, Honeywell, and Mechanix offer certified products directly.

======================================================================================================================

Conclusion

In conclusion, understanding the EN 388 standard and the ISO 13997 test is vital for ensuring the quality and safety of gloves. With clear, standardized methods to measure abrasion, cut, tear, and puncture resistance, you can confidently select gloves that meet the needs of your workplace.