The EN 374 standard is essential when it comes to selecting gloves for chemical and microorganism protection. This certification helps ensure that gloves meet the rigorous safety requirements needed to handle hazardous substances safely.

The EN 374 standard certifies gloves for resistance to chemicals and microorganisms, ensuring the necessary protection for workers in high-risk environments.

For those in charge of purchasing or manufacturing gloves, understanding the EN 374 standard is crucial for ensuring the safety and effectiveness of protective gloves used in hazardous environments. Let’s break down its key components.

What is the EN 374 standard test method?

The EN 374 test method is a comprehensive procedure designed to evaluate how resistant gloves are to chemicals and microorganisms. This testing helps determine which gloves are suitable for handling specific hazardous materials.

The EN 374 test method is a multi-step procedure where gloves are exposed to various chemicals and microorganisms to determine their resistance and ensure proper protection.

The EN 374 test method evaluates gloves under controlled conditions, and the process is quite thorough. There are two major areas of testing: chemical resistance and microorganism protection. Below, we will dive deeper into the details of these two components.

Chemical Resistance Testing:

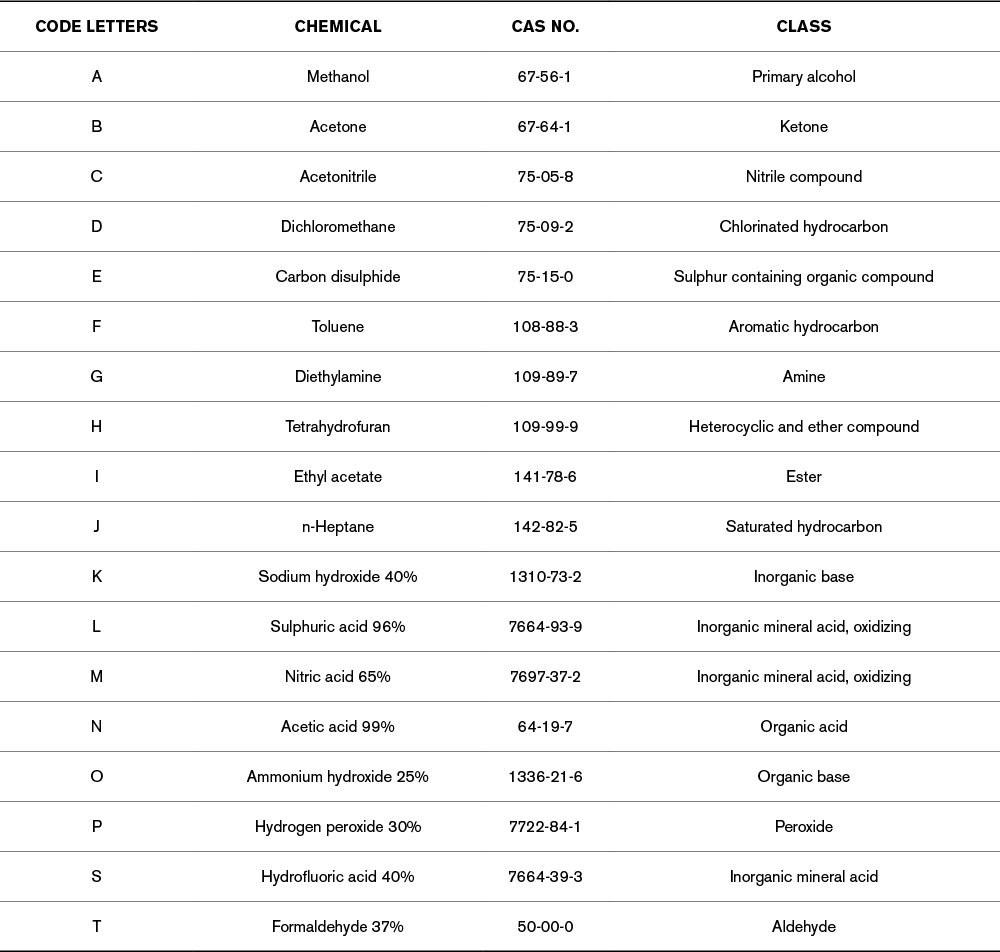

In chemical resistance testing, gloves are immersed in a set of specific chemicals, and the duration it takes for the chemicals to break through the glove material is recorded. This test measures three key factors:

- Permeation: The time it takes for a chemical to break through the glove material at a molecular level.

- Degradation: The degree to which a chemical damages the glove’s physical properties (such as its strength, flexibility, or elasticity).

- Breakthrough time: The point at which the chemical fully penetrates the glove, allowing it to reach the skin. This time can vary depending on the chemical and glove material.

The gloves used in these tests are exposed to a set of chemicals from a predefined list. Typically, the results will show how long the glove can endure without the chemical passing through. The higher the level of resistance, the longer the gloves can be safely used.

Microorganism Protection Testing:

For gloves that are used in healthcare or laboratory environments, protection from microorganisms such as bacteria and viruses is critical. EN 374 also tests gloves for their ability to protect against these risks. Gloves are exposed to a range of microorganisms, and the ability of the gloves to prevent penetration by these pathogens is evaluated.

The test method focuses on assessing the glove’s integrity and whether it remains intact under normal usage. The protection levels are divided into:

- Microorganisms (Type 3)

- Viruses (Type 4)

Key Testing Parameters:

Here’s a summary table of the key parameters in the EN 374 test method for both chemical and microorganism resistance:

| Test Area | Evaluation Factors | Key Parameters |

|---|---|---|

| Chemical Resistance | Permeation, Degradation, Breakthrough Time | Time to permeate or degrade, Material performance under chemical exposure |

| Microorganism Resistance | Pathogen Resistance (e.g., bacteria, viruses) | Ability to block microorganisms, Physical integrity under stress |

What is ISO 374-1 2016 standard?

The ISO 374-1:2016 standard is a global reference for the performance of protective gloves against chemicals and microorganisms. It’s a more specific, internationally recognized extension of the EN 374 standard.

ISO 374-1:2016 specifies the performance requirements for gloves used in environments where chemical or microbial risks exist. It includes clear classifications for glove types based on their chemical protection capabilities.

The ISO 374-1:2016 standard serves as an international extension to the EN 374 and provides a clear and structured approach to testing gloves’ resistance to both chemicals and microorganisms. It also introduces a tiered system for classifying gloves based on their protective properties.

Type Classification System:

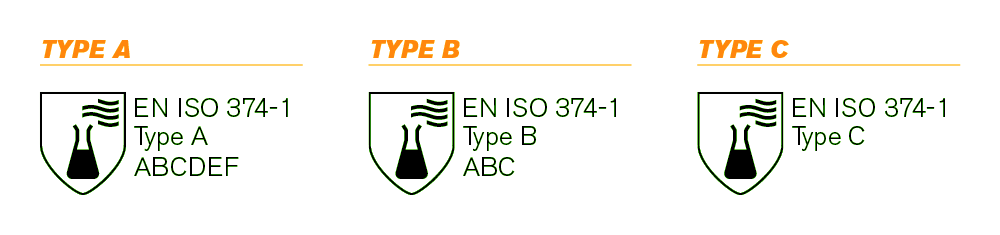

One of the key features of ISO 374-1 is the introduction of the Type A, B, and C classification system. This classification helps users choose gloves based on the specific chemicals they need protection from. Here’s an overview:

- Type A: Provides protection against at least six chemicals from a predefined list of substances. These gloves offer the highest level of chemical resistance.

- Type B: Provides protection against at least three chemicals. They are suitable for handling a smaller range of chemicals but are still reliable for many applications.

- Type C: Provides protection against only one chemical. These gloves are specialized for single-chemical exposure and are not versatile for multiple risks.

Performance Levels:

Another important aspect of ISO 374-1 is its clear, structured performance levels for different glove types. Glove manufacturers must show that their gloves meet certain criteria for each chemical tested. The gloves are then rated, and buyers can easily determine which type offers the best protection based on their specific needs.

Advantages of ISO 374-1:

The ISO 374-1:2016 standard ensures uniformity and global recognition. For companies operating internationally, this standard guarantees that gloves meet the same level of protection across borders, simplifying the procurement process.

ISO 374-1:2016 vs EN 374:

While both standards have similar objectives, ISO 374-1:2016 is often considered more robust because it introduces a global classification system that simplifies the selection of protective gloves.

What is standard EN 374-1?

EN 374-1 is a European standard focused on assessing the resistance of gloves against chemical and microorganism exposure. It helps companies identify which gloves will provide the best protection when handling hazardous materials.

EN 374-1 outlines the performance requirements for protective gloves in terms of chemical resistance and microorganism protection, ensuring they meet the safety standards needed in high-risk environments.

EN 374-1 plays a critical role in the glove industry by setting specific criteria for testing gloves. It has become a benchmark for manufacturers who wish to produce gloves that can protect users from dangerous chemicals and microorganisms.

Chemical Resistance and Breakthrough Time:

EN 374-1 sets high standards for testing gloves against a range of chemicals. Gloves are tested by immersing them in liquids or exposing them to vapors for defined periods, then evaluating the breakthrough time.

- Breakthrough Time: The time it takes for the chemical to permeate the glove material.

- Degradation Index: Measures the physical changes in glove materials when exposed to chemicals.

The standard also provides a list of chemicals that should be used in testing, so manufacturers can evaluate their products’ resistance to substances most commonly encountered in industries like chemical manufacturing or healthcare.

Microorganism Resistance:

In addition to chemical protection, EN 374-1 also tests gloves for resistance against microorganisms, including bacteria and viruses. This is especially important in healthcare settings, where gloves must prevent exposure to harmful pathogens.

Categories of Glove Protection:

EN 374-1 introduces different categories of glove performance based on the chemicals tested:

- Type A (best protection)

- Type B

- Type C (least protection)

Each type corresponds to the number of chemicals the gloves provide protection against, helping buyers select the right gloves based on the risks they face.

What is the difference between EN ISO 374-1 type B and type C?

Understanding the differences between EN ISO 374-1 Type B and Type C gloves is essential when choosing the right protection for specific tasks. Let’s explore the distinctions in chemical protection levels.

The key difference between EN ISO 374-1 Type B and Type C gloves is the number of chemicals they provide protection against. Type B gloves protect against 3 chemicals, while Type C gloves protect against just one.

When selecting gloves, knowing the difference between Type B and Type C gloves can be the deciding factor in ensuring proper protection. These types are both part of the EN ISO 374-1:2016 standard but offer different levels of protection based on the specific hazards involved.

Type B Gloves:

Type B gloves offer a balanced level of protection and are ideal for environments where exposure to a variety of chemicals is expected. They are tested against at least three chemicals from the designated list, offering reliable protection in most scenarios.

- Common Applications: Type B gloves are suitable for industries where workers handle multiple chemicals, including laboratories, chemical manufacturing, and cleaning industries.

Type C Gloves:

On the other hand, Type C gloves are designed to protect users against a single chemical, offering specialized protection in situations where exposure to only one type of substance is expected.

- Common Applications: Type C gloves are often used in controlled environments where only one type of chemical is present, such as chemical testing or handling very specific substances.

Choosing the Right Gloves:

- Type B: Choose these gloves when you need versatile protection against multiple chemicals.

- Type C: These gloves are ideal for specialized applications where exposure to one chemical is the only risk.

Key Comparison Table:

| Feature | Type B Gloves | Type C Gloves |

|---|---|---|

| Number of Chemicals Tested | At least 3 chemicals | 1 chemical only |

| Level of Protection | Moderate (multi-chemical protection) | Specialized (single-chemical protection) |

| Common Use | Chemical labs, cleaning, chemical handling | Specific chemical handling, testing |

| Industry Applications | Chemical, lab, cleaning, industrial | Laboratory, chemical testing, specialized environments |

Conclusion

Understanding the EN 374 standard is essential for selecting the right gloves for chemical and microorganism protection. By considering the differences between glove types, you can ensure that workers are adequately protected based on the specific risks they face.