Working in the cold saps your strength, and frozen fingers make any job ten times harder. Poor grip is a safety risk, and the thought of frostbite is always there.

The solution is to find a glove that balances insulation, a waterproof exterior, and a grippy palm. This ensures your hands stay warm and you maintain full control, no matter the task. It’s about a total system, not just a single feature.

Winter Work Gloves with Good Grip.

I’ve learned a few things over my decade here at BullSafety, mainly that the perfect winter glove1 doesn’t exist. The perfect glove is the one designed specifically for your job. As a PPE wholesaler2, you know your customers’ needs are diverse. They might be in construction, agriculture, or cold storage. Each one requires a different solution. Understanding the key features that make up a winter glove is the first step in finding that perfect solution for your market. Let’s break down what really matters.

What Key Features Should You Look for in Cold-Weather Work Gloves?

With so many gloves on the market, it is hard to choose the right one. A wrong choice means your customers will have cold hands, and you will have wasted inventory.

To make the right choice, focus on a multi-layer construction with a waterproof and windproof outer shell. Look for quality insulation, a palm coating like sandy nitrile for dexterity, and a snug cuff to seal out the cold and snow.

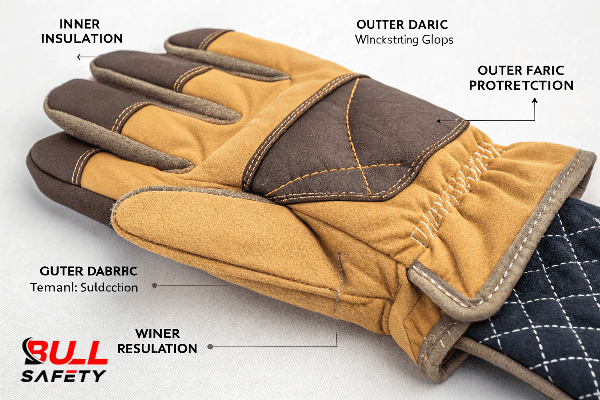

Features of Cold-Weather Work Gloves.

When I consult with a purchasing manager, like Mr. Daniel from a large European distributor, I always start by breaking down the glove’s anatomy3. It’s not just one piece of material; it’s a system where each part has a job. We start with the outer shell, which is the first line of defense. Then, there’s the waterproof membrane4, followed by the insulation layer. Finally, you have the inner liner that sits against the skin. Thinking about it in layers helps you understand the value. Mr. Daniel was struggling to source a single glove for a construction crew with varied tasks. We showed him how different combinations could serve his needs better. It’s about engineering a solution. For any PPE wholesaler, understanding these components is crucial for curating a product line that delivers real performance and safety.

| Feature | Why It Matters for Winter Work |

|---|---|

| Outer Shell | Provides durability and is the first barrier against wind and abrasion. Materials like nylon or polyester are common. |

| Waterproof/Breathable Membrane | Stops water from getting in but allows sweat to escape. This is critical for keeping hands dry from the inside and out. |

| Insulation | Traps body heat to keep hands warm. The type and thickness determine the temperature rating. |

| Liner | The layer next to the skin. It should be soft and moisture-wicking to enhance comfort. |

| Grip Coating | Essential for handling tools and materials safely. The right coating works even in wet or icy conditions. |

| Cuff Style | A longer, adjustable cuff seals the wrist, preventing snow and cold air from entering the glove. |

What Are the Insulation Technologies, From Traditional Fill to Heated Options?

Even with thick gloves, your hands can still get cold. This often means the insulation is not right for the temperature or type of work. Understanding your options is key.

Traditional fills like acrylic terry and Thinsulate offer proven warmth. For extreme cold, some gloves use a double thermal shell5. Newer options even include battery-powered heated gloves6, which provide active, consistent warmth.

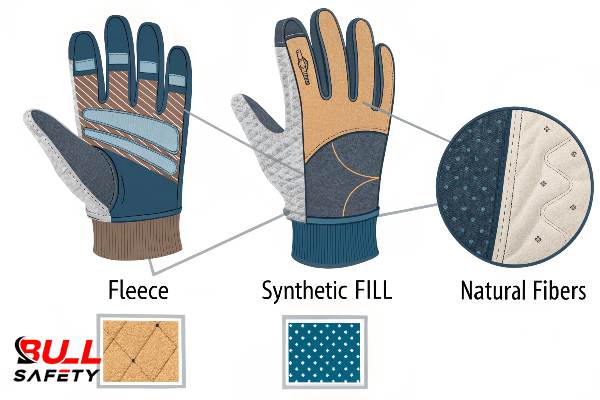

Glove Insulation Comparison.

The world of insulation is always advancing. For years, we relied on materials like goose down, wool, and classic 3M Thinsulate. These are still great options because they trap air effectively, which is what keeps you warm. We manufacture many gloves with a soft acrylic terry liner that provides excellent warmth for its weight. For a client in the Nordic region, we developed a glove with a double-layer liner7 that keeps hands warm in brutally cold weather. As noted in some product descriptions, combinations of acrylic terry and nylon8 can create gloves rated for temperatures as low as -58°F (-50°C).These are designed for the most extreme conditions where passive insulation9 is pushed to its limit. The newest technology gaining traction is heated gloves. While we focus on perfecting passive insulation, it’s an interesting development for specific, low-activity jobs in severe cold.

| Insulation Type | Pros | Cons | Best For |

|---|---|---|---|

| Acrylic Terry | Lightweight, soft, effective warmth, good value. | Can be bulky if not engineered correctly. | General purpose cold weather work. |

| Thinsulate™ | Excellent warmth-to-thickness ratio, good dexterity. | Can be more expensive. | Tasks requiring fine motor skills. |

| Double Thermal Shell | Maximum warmth for extreme cold. | Can reduce dexterity, bulky. | Extreme cold, low-dexterity tasks. |

| Heated Gloves | Provides active, consistent heat. | Requires batteries, more expensive, more failure points. | Sedentary work in extreme cold (e.g., crane operator). |

How Do You Balance Warmth and Dexterity With Material Choices That Matter?

The warmest gloves are often too bulky. This makes it impossible to handle tools, screws, or a phone, slowing you down and causing frustration. The solution is using better materials.

The secret is combining thin, efficient insulation with a flexible outer shell and a high-grip palm. Coatings like microfoam or sandy nitrile give you excellent dexterity and grip without making the glove bulky, which is a focus of our custom designs.

This is perhaps the biggest challenge in glove manufacturing. I remember working closely with Mrs. Caroline Lu, a product manager for a major PPE distributor in Asia. Her customers in the cold storage logistics industry had a big problem. They needed to stay warm in freezing temperatures but also use handheld scanners and handle packages. Their old gloves were warm but clumsy. This is where our OEM capabilities really shine. We worked with her to develop a new glove. We used a seamless, lightweight thermal liner10 and bonded it to a flexible nylon shell. The key was the palm coating. We applied our microfoam nitrile coating11. This coating is porous, so it provides an incredible grip on both wet and dry surfaces, but it’s also extremely flexible. The final product gave her customers the warmth they needed without sacrificing the dexterity to do their jobs efficiently. It’s about choosing the right combination of materials to solve a specific problem.

| Palm Coating | Dexterity | Grip (Wet/Oily) | Best For |

|---|---|---|---|

| Latex | Good | Excellent | Construction, General Handling |

| PU (Polyurethane) | Excellent | Fair | Assembly, Electronics |

| Foam Nitrile | Very Good | Very Good | Logistics, Light Fabrication |

| Sandy Nitrile | Good | Excellent | Oil & Gas, Heavy Construction |

| Microfoam | Excellent | Excellent | Detailed Assembly, Warehousing |

Is it Waterproof vs. Water-Resistant: Choosing the Right Protection Level for Your Work?

The terms "waterproof" and "water-resistant" are often used interchangeably. Choosing the wrong one will lead directly to wet, cold, and unhappy hands on a job site. You need to know the difference.

Water-resistant gloves can handle light snow or a brief shower. But for slush, heavy rain, or wet surfaces, you need truly waterproof gloves. They use a special membrane or a double-coating technology to create a complete barrier against moisture.

Waterproof Work Glove Demonstration.

Let me make this simple. Water-resistant means the fabric is coated to make water bead up and roll off. It works for a while, but with enough pressure or time, water will soak through. Waterproof means there is an impenetrable barrier. At BullSafety, we achieve this in a couple of ways. One way is by inserting a waterproof and breathable membrane between the outer shell and the insulation. Another highly effective method, especially for heavy-duty work, is using a double-dip process12. For instance, we can produce a glove with a full latex dip to seal it, followed by a second palm dip of sandy nitrile for grip. This creates a glove that is 100% waterproof13 on the hand, as mentioned by other manufacturers using similar technology. This is the kind of solution we provide for clients whose customers work in fishing, sanitation, or heavy construction in the winter. It ensures their hands stay dry, period.

| Protection Level | Technology | Best For |

|---|---|---|

| Water-Resistant | Coated fabrics (e.g., DWR finish). | Light snow, dry cold conditions, brief exposure to moisture. |

| Waterproof | Inserted membrane or double-dip coating. | Heavy snow, rain, slush, handling wet objects. |

| Waterproof & Breathable | Microporous membrane. | High-exertion activities in wet conditions to prevent sweating. |

What are the Best Glove Types for Specific Winter Tasks and Tools?

You would not use the same tool for every job. A glove designed for shoveling snow is not going to work well for operating a chainsaw. You have to match the glove to the task.

For shoveling, you need warmth and waterproofing above all else. For power tools, you need superior grip and maybe some vibration resistance. For general tasks, a balanced glove is best. The application determines the ideal features.

Gloves for Specific Winter Tasks.

This is where our role as a specialty manufacturer becomes critical for our wholesale partners. We don’t believe in a one-size-fits-all approach. We excel at creating custom solutions14. This approach, often called a private label or OEM service15, allows us to engineer the perfect glove for a specific market need, a service you will also see offered by other expert manufacturers.For example, for a wholesaler whose customers are primarily in residential snow removal, we would recommend a glove with a thick thermal liner and a fully waterproof latex coating for durability. For another partner who supplies to construction sites, we’d suggest a glove with a sandy nitrile palm for excellent grip on tools, ANSI-rated cut protection, and a flexible thermal liner for dexterity. It is this ability to design, prototype, and manufacture for a specific end-use that provides the most value. We help our partners build a reputation for having the right tool for the job.

| Task | Key Glove Features | Recommended BullSafety Solution (Concept) |

|---|---|---|

| Snow Shoveling | High-level warmth, full waterproofing, durability. | Double-layer thermal liner with a full latex or double-dip coating. |

| Operating Power Tools | Excellent grip, high dexterity, some insulation, and maybe vibration dampening. | Seamless thermal liner with a sandy or microfoam nitrile palm. |

| Cold Storage Logistics | Dexterity for scanners/boxes, moderate warmth, good grip. | Lightweight seamless liner with a flexible foam nitrile palm. |

| General Construction | Durability, impact protection, warmth, cut resistance. | Insulated liner with impact-resistant TPR on the back and a coated grip palm. |

Conclusion

Choosing the right winter glove is a balance of warmth, dexterity, and protection. By partnering with a manufacturer who understands these details, you can deliver real solutions to your customers.

-

Explore this link to understand the essential features of winter gloves tailored for various industries. ↩

-

Learn more about the role of PPE wholesalers and how they meet diverse customer needs in safety gear. ↩

-

Understanding the glove’s anatomy is essential for selecting the right PPE, ensuring safety and performance in various tasks. ↩

-

Exploring waterproof membranes will enhance your knowledge of glove functionality, crucial for making informed purchasing decisions. ↩

-

Learn about the technology behind double thermal shells and how they provide superior insulation for cold weather. ↩

-

Explore this link to discover how battery-powered heated gloves can enhance your comfort and warmth in extreme cold conditions. ↩

-

Learn how a double-layer liner enhances warmth and protection in gloves, especially for extreme cold, and why it might be the best choice for harsh climates. ↩

-

Learn how the combination of acrylic terry and nylon enhances glove insulation, offering superior warmth and performance in extremely cold environments. ↩

-

Learn about passive insulation techniques and materials that keep you warm in brutally cold weather. ↩

-

Discover the advantages of seamless, lightweight thermal liners in gloves, ensuring warmth without compromising dexterity. ↩

-

Explore this link to understand how microfoam nitrile coating enhances grip and flexibility in gloves, crucial for cold storage logistics. ↩

-

Learn about the double-dip process to see how it enhances glove performance and durability for heavy-duty tasks. ↩

-

Learn what ‘100% waterproof’ truly means for work gloves, including the technology and materials used to guarantee complete water protection for your hands. ↩

-

Exploring the benefits of custom solutions can help you optimize your business partnerships and product offerings. ↩

-

Understanding private label or OEM services can enhance your knowledge of custom manufacturing solutions. ↩