Top Microfoam Cut Resistant Gloves Manufacturer in China

------- ISO9001 Certified

CE certificates

ISO14001 Certified

Microfoam cut-resistant gloves are designed with a thin yet durable foam coating, providing excellent protection against cuts without compromising comfort and dexterity.

Microfoam cut-resistant gloves combine a special fiber blend with an ultra-thin foam coating to provide maximum protection from cuts while still allowing flexibility and movement.

These gloves are designed with a thin, breathable foam coating that ensures comfort throughout extended wear, while still providing superior cut resistance.

When compared to leather or nitrile gloves, microfoam cut-resistant gloves offer better protection against sharp objects while being lighter, more flexible, and more breathable.

Light Weight

Microfoam gloves are lightweight due to their thin coating that provides an excellent balance between protection and dexterity, making them comfortable for extended use.

High Durability

Microfoam gloves are surprisingly durable, offering great resistance to wear and tear while maintaining their flexibility even after extensive use.

Ultra Thin

Despite its thinness, microfoam coating offers outstanding protection by using advanced foam technology to maximize both comfort and resilience in harsh working conditions.

Explore High-Performance Hand Protection Solutions

BullSafety is top cut resistant gloves manufacturer , we specialize in providing premium hand protection gloves designed to meet the diverse needs of various industries. Whether you require gloves for high-impact, cut resistance, or general-purpose use, our extensive range of products is tailored to meet the highest standards of safety and comfort. If you have specific needs or designs in mind, we are happy to collaborate with you to create custom solutions that align with your requirements. As a trusted manufacturer, we are committed to delivering durable, cost-effective, and high-performance hand protection for your business. Let’s work together to design the perfect gloves for your clients.

GMF510

Liner: 13 gauge cut resistant gloves

Standards: 4X42E & A5

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMF2313

Liner: 15 gauge graphene gloves

Standards: 4X42C & A3

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMF2613

Liner: 18 gauge cut resistant gloves

Standards: 4X31B & A2

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMFF2613

Liner: 18 gauge cut resistant gloves

Standards: 4X31B & A2

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMF2307

Liner: 15 gauge cut resistant gloves

Standards: 4X42C & A3

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMF2412

Liner: 15 gauge cut resistant gloves

Standards: 4X42D & A4

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

GMF2412

Liner: 18 gauge cut resistant gloves

Standards: 4X42D & A4

Coating Coverage: Palm & Fingers

Add: Thumb Reinforcement & Touchscreen

Grip: Microfoam

Cuff: Knit Wrist

Sizes: M-2XL

Packed: 120 Pair/Case

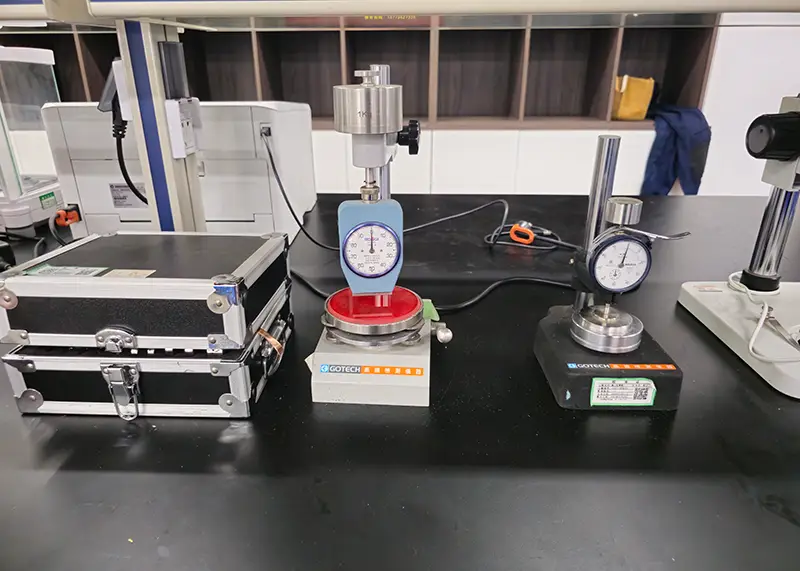

Bull Safety Quality Control Process

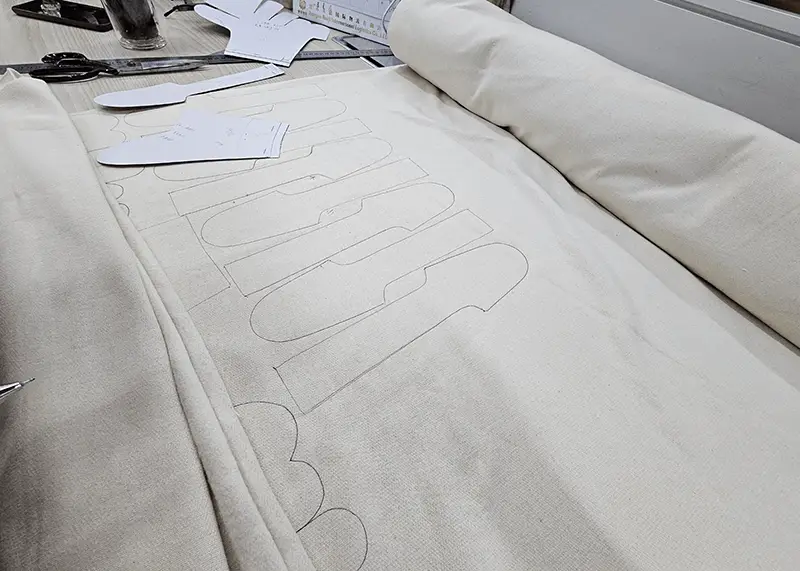

Yarn Inspection for Superior Quality

At BullSafety, we understand that the foundation of a durable glove starts with premium yarn. Our rigorous yarn inspection process ensures every batch meets strict quality and performance standards. By verifying strength, consistency, and elasticity, we guarantee that the materials used in our gloves provide maximum protection and comfort. This meticulous approach helps us deliver reliable products that meet the demands of PPE wholesalers and their customers.

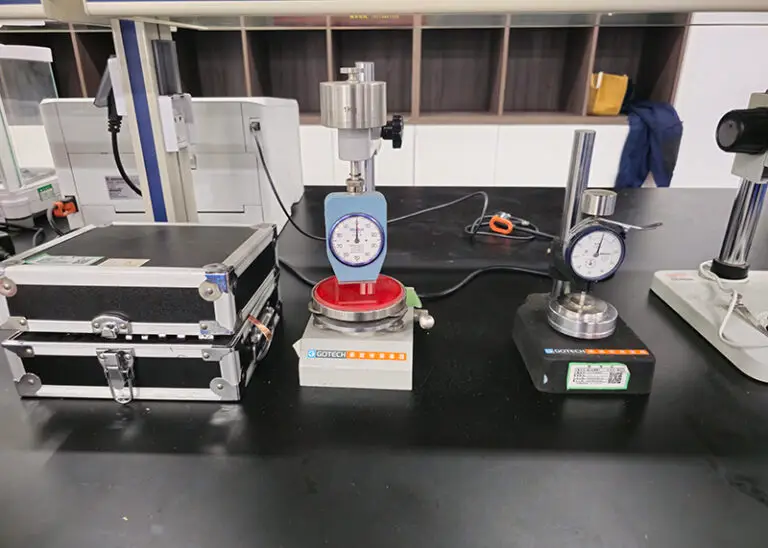

At BullSafety, we carefully measure the weight of each glove to ensure consistent quality and performance. Our precise weight inspection guarantees that gloves meet the required standards for comfort, durability, and protection, without compromising on material efficiency. This attention to detail ensures that every pair of gloves provides the optimal balance between strength and flexibility, making them a reliable choice for wholesalers and their customers.

Glove Size Measurement & Inspection

BullSafety conducts precise glove size measurements to ensure a perfect fit and optimal performance. Our thorough inspection process checks for accuracy in sizing, from small to extra-large, ensuring consistency across all products. By adhering to international sizing standards, we provide gloves that deliver comfort, mobility, and safety, meeting the needs of your customers. Trust our meticulous measurement system for reliable, high-quality gloves every time.

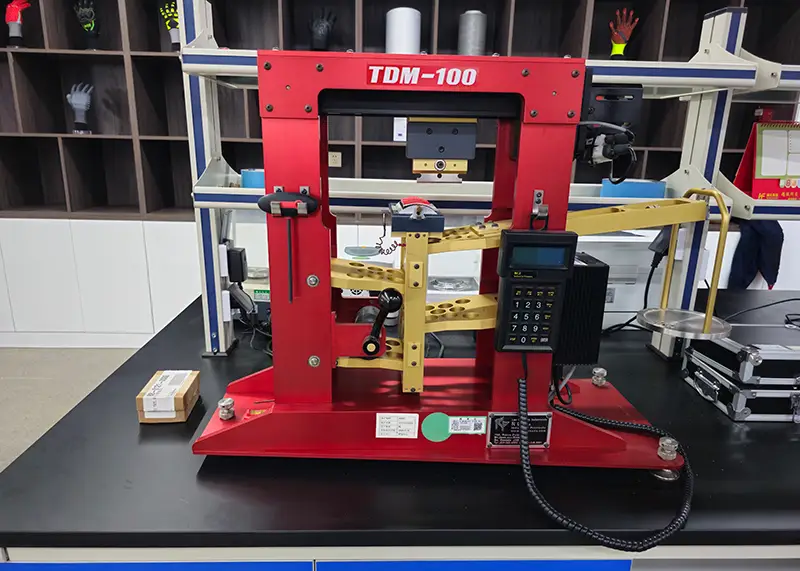

Glove Performance Testing: Abrasion & Cut-Resistance

BullSafety conducts comprehensive performance testing to ensure our gloves meet the highest safety standards. Our abrasion resistance tests evaluate the durability of gloves under repeated friction, ensuring long-lasting protection. Additionally, our TDM cut-resistance tests measure the gloves’ ability to resist sharp objects, providing a reliable indication of their protective qualities. These rigorous tests guarantee that our gloves offer superior performance and safety for your customers, making them a trusted choice for PPE wholesalers.

More Than Just a Glove Supplier

At BullSafety, we are more than just a glove supplier. Our dedication to innovation, quality, and personalized service makes us a trusted partner in the PPE industry. Here’s how we go beyond to support your business:

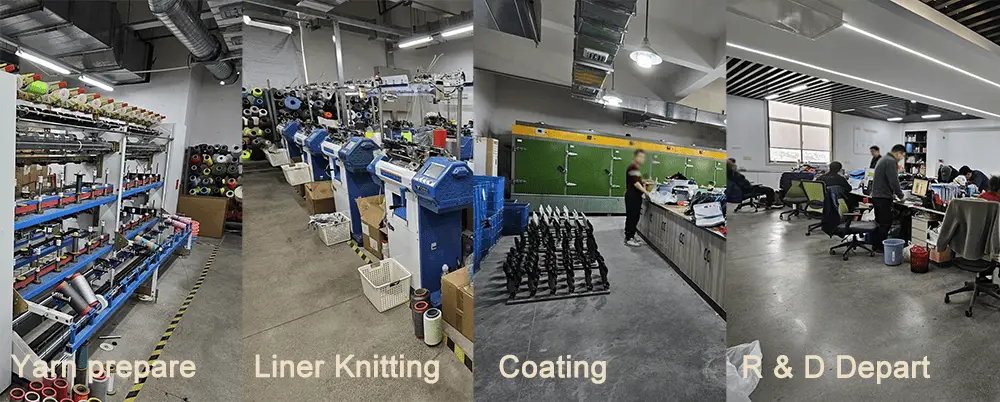

Advanced Manufacturing

We utilize state-of-the-art technology and techniques to produce gloves that meet the highest standards of performance, comfort and durability.

Tailored Solutions

Our expertise also includes tailored fabrication services to meet your unique specifications, no matter what the industry's requirements are including chemical resistance, cut resistance, fine grip, and waterproofing, fireproofing, and insulation.

Diverse Product Range

Our extensive selection includes gloves for specialized needs such as cut resistance, chemical handling, impact protection, and thermal applications.

Expert Guidance

Our team of industry professionals provides comprehensive consultation, helping you choose the right products and solutions to meet market demands and safety requirements.

One Stop Service For You

CERTIFICATES OF BULL SAFETY

One Stop Service For You

Specialized Focus: Produces high-quality yarns tailored for the personal protective equipment (PPE) industry.

Advanced Technology: Utilizes cutting-edge machinery and processes for consistent performance.

Quality Assurance: Ensures durability, strength, and reliability in every batch.

Cost-Effective Solutions: Supports efficient production of top-tier protective gloves.

Specialized Focus: Produces high-quality yarns tailored for the personal protective equipment (PPE) industry.

Advanced Technology: Utilizes cutting-edge machinery and processes for consistent performance.

Quality Assurance: Ensures durability, strength, and reliability in every batch.

Cost-Effective Solutions: Supports efficient production of top-tier protective gloves.

Specialized Expertise: Focuses on high-precision coating for protective gloves to enhance grip, durability, and performance.

Advanced Techniques: Equipped with state-of-the-art coating machines for consistent quality.

Quality Assurance: Ensures superior adhesion, wear resistance, and optimal functionality.

Custom Solutions: Offers tailored coating options to meet diverse industry requirements.

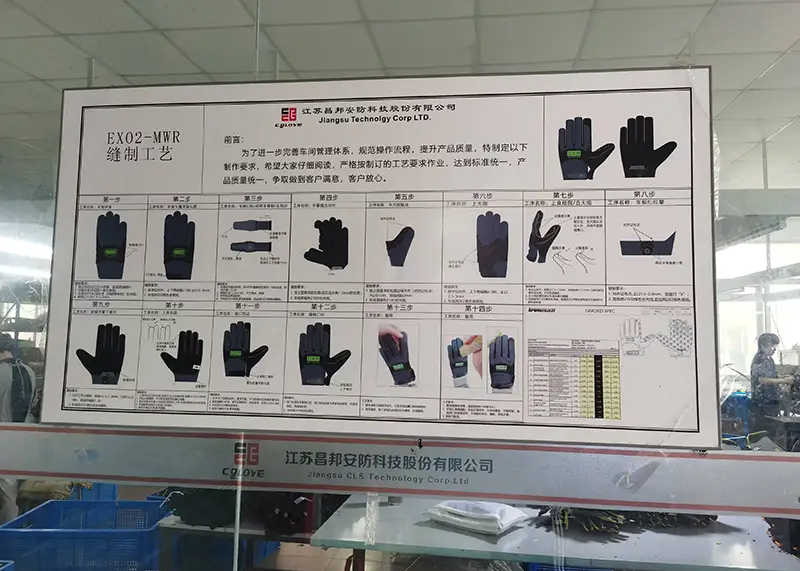

Expert Craftsmanship: Specializes in precision sewing for high-quality protective gloves.

Advanced Equipment: Features modern sewing machines to ensure durability and accuracy.

Stringent Quality Control: Delivers consistent stitching and superior product performance.

Custom Designs: Supports tailored glove solutions to meet specific client needs.

Comprehensive Testing: Equipped to perform rigorous tests for durability, safety, and performance of gloves.

Advanced Equipment: Utilizes state-of-the-art tools to ensure compliance with industry standards.

Quality Assurance: Focuses on maintaining consistent product excellence through in-depth analysis.

Innovation Support: Drives research and development for improved materials and designs.

Efficient Packaging: Ensures gloves are securely packed for safe transport and storage.

Organized Storage: Maintains a well-structured warehouse for easy inventory management.

Your Definitive Guide to Microfoam Cut Resistant Gloves

When looking for a reliable supplier for microfoam cut resistant gloves, here are some key questions you might consider asking:

Chapter 1

Product Specifications

Material Composition:

Microfoam gloves are primarily made from fibers like HPPE (High-Performance Polyethylene), fiberglass, graphene yarns, metal fibers, all coated with a microfoam layer that provides excellent grip and added protection.

The core of microfoam cut-resistant gloves lies in their material composition. These gloves typically use a blend of High-Performance Polyethylene (HPPE) fibers, which are known for their high cut resistance, lightweight nature, and flexibility. HPPE fibers provide excellent protection against cuts while maintaining comfort and dexterity. In addition, fiberglass or aramid fibers may be incorporated to further enhance the glove’s cut resistance.

Another essential component is the microfoam coating. This coating is made from materials like nitrile or polyurethane and is applied to the glove’s surface. The microfoam layer not only adds extra protection against cuts and abrasions but also improves the glove’s grip. Whether you’re working in dry, wet, or oily conditions, microfoam gloves offer superior handling capabilities.

The combination of these advanced materials results in a glove that is strong yet flexible, offering the best of both worlds in protection and usability.

| Material Type | Purpose |

|---|---|

| HPPE (High-Performance Polyethylene) | Cut resistance, lightweight, flexibility |

| Fiberglass | Added strength and durability |

| Aramid fibers | Extra cut and heat resistance |

| Microfoam Coating | Improved grip, abrasion resistance |

| Nitrile/Polyurethane | Chemical resistance and enhanced durability |

Cut Resistance Level:

What Level of Cut Resistance Do the Gloves Provide?

Cut resistance is a major factor when it comes to gloves. Microfoam cut-resistant gloves are designed to meet specific standards for cut protection, ensuring that workers are safe while still able to perform tasks effectively.

These gloves typically meet ANSI/ISEA 105 standards for cut resistance, offering levels from 1 to 5. The higher the level, the more resistant the gloves are to cuts.

Here’s a breakdown of the ANSI cut resistance levels:

| ANSI Level | Cut Resistance (grams) | Suitable Use |

|---|---|---|

| Level 1 | 1-249 grams | Low-risk tasks (e.g., light handling of sharp objects) |

| Level 2 | 250-499 grams | Moderate risk tasks (e.g., packaging) |

| Level 3 | 500-999 grams | Moderate to high-risk tasks (e.g., food processing) |

| Level 4 | 1000-1499 grams | High-risk tasks (e.g., construction, warehousing) |

| Level 5 | 1500+ grams | Very high-risk tasks (e.g., metalworking, glass handling) |

Most microfoam cut-resistant gloves offer levels ranging from 1 to 5, allowing you to choose the level that best suits your specific workplace environment. For example, level 3 gloves may be suitable for general construction or warehousing, while level 5 gloves are best for industries involving sharp machinery or handling glass.

The higher the cut resistance level, the thicker and more durable the glove. However, it’s essential to strike a balance between protection and comfort. Higher-level gloves may feel bulkier, so you’ll want to choose the level that provides sufficient protection without compromising on dexterity and flexibility.

Sizes Available:

Microfoam cut-resistant gloves typically come in a wide range of sizes, from small to XXL, ensuring that workers of all hand sizes can find the perfect fit.

Common sizes range from small to XXL, with many manufacturers offering additional half-size options to accommodate a wide range of hand shapes and sizes. It’s important to consult a detailed sizing chart before purchasing to ensure you’re selecting the right fit. Here’s a sample sizing guide for reference:

| Size | Hand Circumference (inches) | Hand Length (inches) |

|---|---|---|

| Small | 6.3 – 7.1 | 6.5 – 7.0 |

| Medium | 7.2 – 8.0 | 7.1 – 7.5 |

| Large | 8.1 – 8.9 | 7.6 – 8.0 |

| XL | 9.0 – 9.8 | 8.1 – 8.5 |

| XXL | 9.9 – 10.6 | 8.6 – 9.0 |

Make sure to measure your hand properly to find the ideal glove size. Ill-fitting gloves not only reduce comfort but can also compromise the protective capabilities of the gloves.

Color Options:

Yes, we can provide test reports for all our cut-resistant gloves. These reports are carried out by accredited third-party testing laboratories and ensure that our products meet the relevant safety standards.

- ANSI/ISEA Testing: We conduct thorough cut-resistance tests according to the ASTM F1790 standard, ensuring that our gloves pass the necessary requirements for different cut-resistance levels (e.g., A1 to A9).

- EN388 Testing: We provide detailed EN388 test reports, showing the results of the abrasion, cut, tear, and puncture tests, which are critical for understanding the durability of the gloves in various work environments.

Certifications:

Do the Gloves Comply with Relevant Safety Standards and Certifications?

Yes, microfoam gloves typically comply with international safety standards such as EN388, ASTM, and ANSI/ISEA, ensuring high levels of cut protection.

Safety standards and certifications play a key role in evaluating the reliability of protective gear. Microfoam cut-resistant gloves are often tested to meet the EN388 standard, which measures the glove’s performance in four categories: abrasion, cut, tear, and puncture resistance. EN388 gloves are rated with a score of 1 to 4 for each category, and higher scores indicate better protection.

For example, EN388 rating “4X43F” means the glove performs well in abrasion (4), and offers decent cut resistance (X) with high puncture resistance (4). Additionally, gloves that comply with ASTM and ANSI/ISEA standards offer further assurance of their performance in handling sharp objects and hazardous conditions.

| Standard | Purpose | Rating System |

|---|---|---|

| EN388 | Mechanical risks (abrasion, cut, puncture) | 1-4 for each category |

| ASTM F1790-97 | Cut resistance (measured in grams) | 1-5 levels |

| ANSI/ISEA 105 | Cut resistance in various conditions | Level 1 to Level 5 |

Chapter 2

Quality Assurance

Quality Control Processes:

Quality control in microfoam cut-resistant gloves involves multiple stages, including raw material inspection, production monitoring, and final product testing, ensuring consistency and high standards.

Microfoam cut-resistant gloves are subjected to a stringent quality control process to ensure that they meet the highest standards for durability, protection, and performance. The process typically involves several key stages:

Raw Material Inspection:

The quality of the fibers and coatings used in glove production is the first line of defense against defects. High-performance fibers such as HPPE (High-Performance Polyethylene), fiberglass, or aramid are inspected for consistency in thickness, tensile strength, and cut-resistance properties. Any inconsistencies in raw materials can impact the final product’s performance.Production Monitoring:

Throughout the manufacturing process, strict monitoring takes place to check for potential issues such as incorrect weaving, poor coating application, or uneven dipping. Automated machines help maintain uniformity, but human inspections are also crucial at every stage, including during the core weaving and microfoam coating applications.Final Product Testing:

Once the gloves are assembled, they go through a final inspection to check for defects like holes, improper stitching, or inconsistent foam application. They are also checked for proper sizing, comfort, and fit.

In addition to these internal checks, manufacturers often use advanced technology, such as machine vision systems, to identify defects that might go unnoticed during human inspections. This ensures a high level of precision, reducing the chance of defective gloves reaching the market.

| Quality Control Step | Purpose |

|---|---|

| Raw Material Inspection | Ensures consistency in fiber strength and cut resistance |

| Production Monitoring | Prevents defects like uneven coating or poor stitching |

| Final Product Testing | Confirms glove durability, fit, and overall quality |

Testing Procedures:

How Are the Gloves Tested for Durability and Performance?

Microfoam cut-resistant gloves are tested using both mechanical tests (like abrasion, puncture, and cut resistance) and real-world performance simulations to ensure they withstand harsh conditions.

Testing is one of the most critical aspects of quality assurance for microfoam cut-resistant gloves. These gloves are subjected to a series of standardized tests to measure their durability, cut resistance, and performance under various conditions. Some of the key tests include:

Cut Resistance Testing:

The most critical test for cut-resistant gloves is the cut resistance test, usually done under standards like ANSI/ISEA 105 (American National Standards Institute) and EN388 (European Standard). The gloves are subjected to a blade or rotating circular blade, and the amount of force it takes to cut through the material is measured. The higher the resistance, the better the glove will perform in environments with sharp objects.The ANSI cut resistance is measured in grams and is rated on a scale from 1 to 5. Gloves that score a level 5 offer the highest cut protection.

Abrasion Resistance Testing:

Abrasion tests simulate the wear and tear that gloves undergo during regular use. A mechanical test grinds the glove against abrasive materials like sandpaper or rough surfaces to simulate long-term usage. The goal is to ensure the gloves don’t lose their protective qualities too quickly, particularly in high-friction environments.Puncture Resistance Testing:

Puncture resistance testing assesses how well the gloves can withstand sharp objects like nails or screws. In this test, a puncturing device is used to simulate objects workers might encounter in fields like construction or metalworking. Gloves that pass this test provide extra protection in environments where sharp tools and machinery are used.Chemical and Environmental Testing:

Depending on the intended use of the gloves, chemical resistance may also be tested. Microfoam gloves can be coated with materials like nitrile, which is tested for resistance to various chemicals, including oils, greases, and certain solvents. The gloves may also be exposed to extreme temperatures or wet conditions to evaluate their performance in different environments.

| Test Type | Purpose |

|---|---|

| Cut Resistance Testing | Measures resistance to cuts and sharp objects |

| Abrasion Resistance Testing | Simulates wear and tear to ensure long-lasting durability |

| Puncture Resistance Testing | Ensures protection against punctures from sharp objects |

| Chemical Resistance Testing | Tests the glove’s resistance to oils, chemicals, and solvents |

Certifications of Quality:

Can You Provide Certificates or Documentation for Quality Assurance?

Microfoam cut-resistant gloves are certified under various international standards such as EN388, ANSI/ISEA 105, and ISO 9001, ensuring they meet high safety and performance benchmarks.

Certifications play a crucial role in verifying that gloves meet the necessary safety and performance standards. Some of the most recognized certifications for microfoam cut-resistant gloves include:

EN388:

As one of the most widely recognized standards for cut-resistant gloves in Europe, EN388 measures performance in four categories: abrasion resistance, cut resistance, tear resistance, and puncture resistance. A high EN388 score indicates that the gloves provide excellent protection in industrial and construction environments.ANSI/ISEA 105:

The ANSI/ISEA 105 standard is the benchmark for cut resistance in the U.S. It uses a blade test to measure how many grams of force are needed to cut through the glove material. Microfoam gloves can achieve levels ranging from 1 to 5, with higher numbers indicating better cut resistance.ISO 9001 Certification:

The ISO 9001 certification is a global quality management standard that ensures manufacturers meet rigorous quality control processes. ISO 9001 certification assures customers that the gloves are produced according to consistent quality standards and that the manufacturing process is continuously evaluated and improved.Oeko-Tex Certification:

Oeko-Tex is another important certification that ensures gloves are free from harmful substances. It is especially important for gloves used in food processing or for workers with sensitive skin.CE Certification:

Gloves sold in the European Union often carry the CE mark, indicating they meet the European health, safety, and environmental protection standards. This certification is essential for companies looking to distribute gloves in EU markets.

| Certification | Purpose |

|---|---|

| EN388 | Measures cut, abrasion, tear, and puncture resistance |

| ANSI/ISEA 105 | U.S. standard for cut resistance |

| ISO 9001 | Ensures consistent quality control |

| Oeko-Tex | Certifies gloves are free from harmful chemicals |

| CE Certification | Ensures compliance with EU safety and health standards |

Chapter 3

Samples and Customization

Sample Availability: Can You Provide Samples for Quality Evaluation Before Placing a Bulk Order?

Yes, we offer samples of our microfoam cut-resistant gloves to allow you to assess their quality, performance, and fit before you place a larger order, ensuring you get exactly what you need.

When purchasing work gloves, especially in bulk, it’s vital to ensure the product meets your exact requirements. We understand that businesses need confidence in their products, and we offer the opportunity to evaluate samples before making a larger commitment.

Free Sample Request:

Many suppliers, including us, offer free or low-cost samples of microfoam cut-resistant gloves. These samples allow you to assess the quality, durability, and comfort of the gloves before placing a bulk order. You can request different sizes, styles, or even variations in the material to make sure the gloves are suitable for your specific needs, whether for construction, manufacturing, or food processing.Custom Sample Requests:

If you have specific features or customizations in mind, we can provide tailored samples. Whether it’s a different coating type (such as nitrile or PU), a specific level of cut resistance, or particular sizes, requesting a sample will allow you to see and feel the gloves in real-life conditions before committing.Testing Samples:

Beyond just evaluating the fit and comfort, it’s important to test the gloves for performance. Testing for cut resistance, abrasion resistance, and grip can give you a better idea of how the gloves will perform in your industry. We encourage you to test the gloves in the environments where they will be used, ensuring they meet your expectations.Lead Times for Samples:

Lead times for receiving samples can vary. Generally, once you request a sample, it can take anywhere from 1-2 weeks to arrive, depending on the region and shipping conditions. Once you receive the sample, you can start evaluating it based on your quality benchmarks.

| Sample Type | Purpose |

|---|---|

| Free Sample Request | Allows you to evaluate the glove quality before a bulk order |

| Custom Sample Requests | Tailored samples with specific features or sizes |

| Testing Samples | Hands-on testing for durability, comfort, and fit |

By offering samples, we ensure you are fully confident in the gloves you plan to order, eliminating any concerns about quality or performance in your workplace.

Customization Options: Do You Offer Customization in Terms of Branding, Packaging, or Specific Product Features?

Yes, we offer extensive customization options, including branding (logos and tags), specialized packaging, and even adjustments to the product features, such as color, cut resistance level, and coating types.

Customization is an essential part of the ordering process, especially for businesses that want their products to stand out or meet specific operational requirements. Here’s how we can help:

Branding Customization:

We understand that branding is important for businesses, and we offer several options for customizing microfoam cut-resistant gloves with your company logo or design. Whether you need a simple logo printed on the cuff or a full-custom branded label, we can print or embroider logos onto the gloves for added brand visibility. This is especially important for companies that distribute gloves to customers or use them as part of their uniform or protective gear.Custom Colors: If you need your gloves to match your brand colors, we can often offer a variety of colors for the foam coating or fabric, giving your gloves a professional and consistent look.

Company Labels and Tags: Custom labels with your company’s name, safety instructions, or care guidelines can be sewn into the gloves. This helps your customers or employees know they are using your brand’s trusted protective gear.

Packaging Customization:

Packaging is another area where customization adds value. Whether you need bulk packaging for larger shipments or individual packaging for retail purposes, we can work with you to design the right packaging solution. You can choose from eco-friendly materials, custom boxes, or poly bags with your brand’s design and safety instructions printed on them. Packaging that reflects your brand’s identity is key, especially if you’re distributing to clients or reselling to end consumers.Product Feature Customization:

If you have specific requirements for your gloves, we offer feature customization. You can request gloves with:- Adjustable cuffs or elasticated wristbands for a better fit

- Enhanced grip for more demanding tasks, with specialized coating or texturing

- Specialized coatings like nitrile or latex for added oil resistance or chemical protection

- Touchscreen compatibility for gloves designed to be used with mobile devices or machinery screens

Minimum Order Quantities (MOQs) for Customization:

While customization can significantly enhance the appeal of your gloves, it often requires a higher minimum order quantity (MOQ). Depending on the customization request (branding, packaging, and special features), MOQs can range from 500 to 1,000 pairs or more. However, this investment allows you to receive gloves tailored specifically for your business needs.

| Customization Type | Description |

|---|---|

| Branding (Logo/Tags) | Adds logos or custom branding to gloves for brand visibility |

| Packaging Customization | Tailors packaging for bulk or retail needs |

| Product Feature Customization | Adjusts glove features like grip, coating, and size |

| Minimum Order Quantities | Higher MOQs for custom features or designs |

Chapter 4

After-Sales Support

Return Policy: What Is Your Return Policy for Defective or Unsatisfactory Products?

If the gloves are defective or unsatisfactory, we offer a flexible return policy, ensuring that you can either receive a replacement or a refund, depending on the situation and your preference.

Having a reliable return policy is an essential part of ensuring customer satisfaction, especially when purchasing in bulk. In the case of our microfoam cut-resistant gloves, we aim to handle any issues quickly and fairly.

Conditions for Returns:

- Defective Products: If the gloves are damaged or defective upon arrival, we will accept returns and either issue a replacement or a full refund. Defects can include manufacturing errors, incorrect sizing, or issues with the cut resistance of the gloves.

- Unsatisfactory Products: If the gloves do not meet the specifications agreed upon or are not what you expected in terms of design or performance, we also accept returns, provided you notify us within a reasonable period, typically within 30 days of receiving the product.

Return Process:

We make returns easy with a straightforward process. Simply contact our customer support team and provide your order details, photos of the defective or unsatisfactory product, and a brief explanation of the issue. Our team will guide you through the return steps, including issuing return labels if necessary. Once the return is received, we process the refund or send a replacement.Shipping Costs:

For defective or incorrect items, we generally cover the return shipping costs. If the return is due to a customer change of mind (not related to defects), the customer may be responsible for shipping fees.Timeframe for Returns:

The time allowed for returns is typically 30 days after receiving the product, but we are open to negotiations depending on the situation. If you need a longer period due to operational constraints, just let us know.

| Return Reason | Action Taken |

|---|---|

| Defective Products | Full refund or replacement offered |

| Unsatisfactory Quality | Full refund or replacement, within 30 days |

| Customer Change of Mind | Refund possible, customer pays return shipping fees |

Customer Support: How Can I Reach Your Customer Support for Ongoing Assistance?

Our customer support is available via multiple channels, including email, phone, and live chat. We’re here to assist with product inquiries, returns, warranties, and any other questions you may have.

Reliable customer support is critical to ensuring a smooth experience when buying and using microfoam cut-resistant gloves. Here’s how you can reach us for ongoing support:

Email Support:

You can reach our customer support team by emailing us directly at sales@bullsafety.com. Our team is responsive and will get back to you with a solution within 24–48 hours. This is the best option for issues that require detailed documentation or if you need to send in images for returns or warranty claims.Phone Support:

For immediate assistance, feel free to call us during business hours. Our customer service phone line is available at +86-123-456-7890. Whether you need help with product selection, troubleshooting, or placing a follow-up order, our team will be happy to guide you.Live Chat Support:

We also offer live chat support on our website. This option is great for quick inquiries or assistance with your order. Simply click the chat icon at the bottom right of the screen, and our team will be ready to assist you in real-time.Business Hours:

Our customer support team is available Monday through Friday, from 9 AM to 6 PM (China Standard Time). If you need after-hours support, we’ll do our best to respond as soon as we can, or we can schedule a call for a later time.

| Support Method | Availability |

|---|---|

| Email Support | 24/7 response, average reply time 24-48 hours |

| Phone Support | Monday–Friday, 9 AM–6 PM (China Standard Time) |

| Live Chat Support | Available during business hours |

Chapter 5

Sustainability and Ethical Practices

Sustainable Materials: Do you use eco-friendly or sustainable materials in your gloves?

Yes, we incorporate sustainable materials, such as recycled fibers and eco-friendly coatings, to reduce our environmental footprint while maintaining the durability and performance of our gloves.

Sustainability is a priority in our glove manufacturing process, as we strive to minimize our environmental impact while offering high-quality products. Here’s how we incorporate eco-friendly materials:

Recycled Fibers:

In the production of our microfoam cut-resistant gloves, we use recycled fibers where possible. This reduces the demand for virgin materials and helps keep plastic waste out of landfills. The use of recycled fibers doesn’t compromise the quality of the gloves but instead ensures that we’re contributing to a more circular economy.Eco-Friendly Coatings:

The microfoam coating used on our gloves is made from water-based, eco-friendly materials that reduce the harmful impact of traditional, solvent-based coatings. This ensures that our gloves are not only durable but also safer for the environment during their production and after their lifecycle.Sustainable Packaging:

In addition to using sustainable materials for the gloves themselves, we also focus on minimizing the environmental impact of our packaging. We use recyclable materials for packaging and reduce excess packaging to minimize waste. Our goal is to make sure that even the delivery process is as eco-friendly as possible.Efficient Manufacturing Processes:

To further reduce waste and environmental impact, we have invested in energy-efficient machines and optimized production lines. By using less energy and reducing waste, we decrease the carbon footprint of each pair of gloves produced.

| Material Type | Sustainability Features |

|---|---|

| Recycled Fibers | Reduces the need for virgin materials, minimizes waste |

| Eco-Friendly Coatings | Water-based, non-toxic, and safer for the environment |

| Sustainable Packaging | Use of recyclable materials and minimized packaging |

| Efficient Manufacturing | Reduced energy consumption and waste |

Ethical Manufacturing: What are your labor practices and ethical standards in manufacturing?

We are committed to ethical labor practices, ensuring fair wages, safe working conditions, and respect for workers’ rights in every part of our glove manufacturing process.

Ethical manufacturing is at the core of our production philosophy. We believe that ensuring the well-being of our workers is just as crucial as delivering quality products. Here’s how we ensure ethical labor practices:

Fair Wages and Benefits:

We provide fair wages that meet or exceed the minimum wage requirements in our region. Additionally, we offer benefits such as healthcare, paid time off, and bonuses based on performance. This ensures that our workers are compensated fairly for their hard work and dedication.Safe Working Conditions:

We are fully committed to providing a safe and healthy working environment. Our factories are regularly inspected to ensure that safety protocols are strictly followed. This includes providing proper personal protective equipment (PPE) to workers, ensuring that machines are properly maintained, and minimizing exposure to hazardous materials. We also train workers regularly on workplace safety and emergency procedures.Respect for Workers’ Rights:

We strictly adhere to labor laws and international standards that protect workers’ rights. This includes eliminating child labor, forced labor, and discrimination. Our workers are free to join unions and have the right to voice concerns without fear of retaliation. We believe in providing a supportive and respectful work environment.Transparency and Audits:

We regularly conduct third-party audits to ensure compliance with labor and environmental standards. These audits are designed to verify that we are meeting the highest ethical standards in our manufacturing process. We also welcome independent inspections to ensure transparency and continuous improvement in our practices.

| Ethical Standard | Our Practices |

|---|---|

| Fair Wages and Benefits | Above minimum wage, healthcare, paid time off |

| Safe Working Conditions | Regular safety training, proper PPE, machine maintenance |

| Respect for Workers’ Rights | No child labor or forced labor, workers’ right to unionize |

| Transparency and Audits | Regular third-party audits, open inspections |

Chapter 6

Technology and Innovation

Product Innovation: Are You Investing in Any New Technologies or Innovations for Your Gloves?

Yes, we are constantly investing in new technologies and innovations, such as advanced coating materials, enhanced cut resistance, and ergonomic designs, to improve the performance and comfort of our gloves.

Innovation is the key to providing our customers with the best possible protection, comfort, and durability. Here’s how we integrate the latest technologies into our microfoam cut-resistant gloves:

Advanced Coating Technologies:

We continuously explore new coating materials and technologies that enhance the glove’s cut resistance, grip, and flexibility. The microfoam coating, which provides a superior balance of cut protection and dexterity, has been refined using the latest advancements in polymer chemistry. This makes our gloves more comfortable, long-lasting, and resistant to wear and tear.Enhanced Cut Resistance:

As part of our ongoing innovation efforts, we are working on incorporating higher-performance fibers like HPPE (High-Performance Polyethylene) and glass fiber into our glove construction. These materials significantly improve the glove’s cut resistance without compromising flexibility or comfort. We focus on achieving higher ANSI cut levels, which means our gloves provide greater protection against sharp objects in various work environments.Ergonomic Design Improvements:

We understand that comfort plays a critical role in glove performance. To address this, we are incorporating ergonomic designs into our gloves. This includes anatomical shaping and improved fit, ensuring that the gloves provide maximum comfort during long hours of use. The goal is to reduce hand fatigue while maintaining a high level of dexterity and control.Smart Glove Integration:

We are also exploring the integration of smart technology into our gloves. This could include built-in sensors to monitor hand movement or provide feedback on glove wear over time. With the advent of wearable tech, we are investing in innovations that could one day offer real-time data on the performance of the gloves, such as detecting excessive wear or providing alerts when the gloves need replacement.

| Technology/Innovation | Benefits |

|---|---|

| Advanced Coating Technologies | Better grip, improved cut resistance, flexibility |

| Enhanced Cut Resistance with HPPE | Higher protection against sharp objects, durable |

| Ergonomic Design Improvements | Reduces hand fatigue, improved comfort, better fit |

| Smart Glove Integration | Real-time monitoring, wear alerts, improved performance |

R&D Capabilities: Do You Have Research and Development Capabilities to Improve Product Features?

Yes, we have a strong R&D department focused on continuously improving the functionality, durability, and safety of our gloves, using both in-house testing and industry collaborations to drive innovation.

R&D is crucial in staying ahead of the competition and adapting to the changing needs of our customers. Here’s how our R&D capabilities help improve the features of our microfoam cut-resistant gloves:

In-House Testing and Prototyping:

Our R&D team works closely with material scientists and engineers to test and prototype new materials, coatings, and designs for our gloves. We use advanced testing methods, including cut resistance testing, abrasion testing, and dexterity evaluations, to ensure that our gloves meet the highest performance standards before they are brought to market.Industry Collaboration:

We understand the importance of staying ahead in a rapidly evolving industry. As part of our commitment to R&D, we collaborate with leading institutions and industry experts to share knowledge and gain insights into new technologies and materials. These partnerships enable us to adopt cutting-edge innovations and stay at the forefront of glove technology.Customer Feedback Integration:

We actively gather feedback from customers to understand how our gloves are performing in real-world conditions. This valuable input is essential for improving our product features and identifying areas for innovation. Whether it’s enhancing comfort, improving cut resistance, or adding new features like touchscreen compatibility, customer feedback plays a pivotal role in our R&D process.Continuous Product Improvement:

The process of innovation is never static. Our R&D team is continuously improving our gloves by refining existing designs and exploring new possibilities. This includes working on achieving higher cut resistance levels, developing more durable materials, and introducing additional features like water resistance or flame retardancy to meet the specific needs of different industries.

| R&D Focus Area | Impact on Product Features |

|---|---|

| In-House Testing and Prototyping | Ensures gloves meet high performance and safety standards |

| Industry Collaboration | Access to the latest materials and technologies |

| Customer Feedback Integration | Tailors products to meet real-world needs |

| Continuous Product Improvement | Develops more durable, high-performance gloves |

FAQs of Microfoam Cut Resistant Gloves

What materials are used in your microfoam cut resistant gloves, and how do they enhance protection and comfort?

Our microfoam cut resistant gloves are made using high-quality materials such as Kevlar fibers, stainless steel, and durable microfoam padding. Kevlar provides excellent cut resistance, while stainless steel fibers add extra protection against sharp objects. The microfoam padding ensures that the gloves are comfortable to wear for long periods, reducing hand fatigue and enhancing overall user experience.

Do your gloves hold relevant certifications such as CE, ANSI, and ISO, and can you provide documentation for compliance?

Yes, our gloves are CE certified and comply with ANSI standards. Our manufacturing processes are ISO9001 and ISO14000 certified, ensuring that our products meet international quality and environmental standards. We can provide all necessary documentation to verify our certifications and compliance upon request.

What is your pricing structure for bulk orders, and how do you ensure cost-effectiveness without compromising quality?

We offer competitive pricing for bulk orders, tailored to the quantity and specific requirements of each client. By optimizing our manufacturing processes and sourcing high-quality materials at cost-effective rates, we ensure that our gloves remain affordable without sacrificing quality. We also provide discounts for larger orders to enhance cost-effectiveness for our partners.

Can you customize the gloves in terms of size, color, branding, and specific features to meet our company's requirements?

Absolutely. We offer extensive customization options including various sizes, colors, and branding with your company logo. Additionally, specific features such as enhanced grip, additional padding, or specialized coatings can be tailored to meet your unique requirements, ensuring that the gloves align perfectly with your brand and operational needs.

What are your lead times for large-scale orders, and how do you ensure timely delivery to prevent stockouts?

Our typical lead time for large-scale orders is between 5 to 8 weeks, depending on the customization and order volume. We maintain a reliable production schedule and have a robust logistics network to ensure timely delivery. In cases of high demand, we prioritize orders to prevent stockouts and ensure that your supply chain remains uninterrupted.

How do your gloves address ergonomics and comfort to reduce hand fatigue for workers during extended use?

Our gloves are designed with ergonomics in mind, featuring microfoam padding that provides cushioning and reduces pressure on the hands. The flexible materials allow for a natural range of motion, enhancing comfort during extended use. Additionally, the gloves are lightweight yet durable, minimizing hand fatigue and improving overall productivity.

What after-sales support and customer service do you offer, including handling returns, replacements, and technical assistance?

We provide comprehensive after-sales support to ensure customer satisfaction. This includes handling returns and replacements for any defective products, as well as offering technical assistance for product-related inquiries. Our dedicated customer service team is available to address any issues promptly and ensure that your experience with our products remains positive.

How durable are your microfoam cut resistant gloves, and what measures do you take to ensure long-term wear resistance?

Our microfoam cut resistant gloves are built to withstand rigorous use, offering excellent durability and long-term wear resistance. We use high-quality materials and advanced manufacturing techniques to enhance the strength and resilience of the gloves. Regular quality checks and stringent testing processes ensure that each pair meets our high standards for durability.

Can you provide samples of your gloves for evaluation before committing to a large purchase?

Yes, we can provide samples of our microfoam cut resistant gloves for your evaluation. This allows you to assess the quality, comfort, and performance of our products before making a larger commitment. Please contact our sales team to request samples and discuss your specific requirements.

How reliable is your supply chain, and what contingency plans do you have in place to handle urgent or unexpected orders?

Our supply chain is highly reliable, supported by strong relationships with our suppliers and efficient logistics partners. To handle urgent or unexpected orders, we have contingency plans in place, including backup suppliers and flexible production schedules. This ensures that we can meet your needs promptly, even in challenging circumstances, maintaining a steady and dependable supply of our gloves.