Choosing the wrong work gloves leads to failures, potential injuries, and lost time. You need reliable hand protection that stands up to tough conditions every day.

Nitrile coated safety gloves are a top choice because they offer excellent durability, strong resistance to oils and punctures, and versatile grip options suitable for many industries. They provide reliable protection without the allergy concerns of latex.

Selecting the right safety glove is crucial for any purchasing manager or PPE wholesaler. Your customers depend on you to provide gloves that protect workers effectively and offer good value. Nitrile coated gloves have become incredibly popular, and for good reason. But understanding the specific features and applications helps you make the best choice for your inventory. Let’s dive into what makes these gloves stand out and where they perform best. As a manufacturer, we at BullSafety have spent years refining nitrile coatings and glove designs to meet the real-world needs of workers across many sectors.

What are nitrile coated gloves used for?

Are you unsure if nitrile coated gloves are the right fit for your customers’ tasks? Using the wrong glove type can compromise safety and reduce work efficiency significantly.

Nitrile coated gloves are used in industries like automotive, manufacturing, construction, assembly, oil & gas, and general maintenance. Their oil resistance, durability, and grip make them ideal for handling parts, tools, and materials in various conditions.

Nitrile coated gloves are true workhorses in the PPE world. Their unique properties make them suitable for a remarkably wide range of jobs. At BullSafety, we’ve supplied nitrile gloves to clients across almost every major industry, and we’ve seen firsthand where they excel.

- Automotive and Machinery: Mechanics and assembly workers constantly handle oily parts, fluids, and tools. Nitrile’s excellent resistance to oils, fuels, and greases keeps hands protected and maintains grip. Sandy or microfoam nitrile coatings are highly recommended for superior oil grip1.

- Manufacturing and Assembly: Workers benefit from nitrile gloves’ abrasion resistance2 and dexterity. Foam nitrile is preferred for its grip in both wet and dry conditions.

- Construction and Mining: Tough environments require tough gloves. Thicker nitrile coatings on durable liners offer protection against scrapes and punctures. Smooth nitrile is great for wet concrete work due to its waterproofing.

- Oil & Gas: Workers need gloves that resist petrochemicals3 and offer a strong grip. Sandy nitrile finishes perform exceptionally well.

- Logistics and Warehousing: Nitrile gloves provide the durability4 needed for package handling and warehouse duties.

- Gardening and Landscaping: Nitrile gloves offer protection against punctures and chemicals while being easy to clean.

| Industry | Key Benefit of Nitrile | Common Coating Type | Recommended Liner Gauge |

|---|---|---|---|

| Automotive | Oil Resistance, Grip, Durability | Sandy, Microfoam | 13g, 15g, 18g |

| Manufacturing | Dexterity, Abrasion Resistance, Grip | Foam, Microfoam | 15g, 18g, 21g |

| Construction | Durability, Puncture Resistance | Smooth, Sandy | 13g, 15g |

| Oil & Gas | Oil/Chemical Resistance, Grip | Sandy | 13g, 15g |

| Assembly | Dexterity, Tactile Sensitivity | Foam, Microfoam | 18g, 21g |

| General Maintenance | Durability, Versatility | Foam, Sandy | 15g |

| Gardening | Puncture Resistance, Waterproofing | Smooth, Foam | 15g |

What are the features of nitrile coated gloves?

With so many glove types available, focusing on the specific features can feel confusing. Choosing based on price alone, without understanding the features, often leads to poor performance and dissatisfied workers.

Nitrile coated gloves feature excellent oil resistance, superior durability, and strong grip, making them ideal for handling parts, tools, and materials in wet, oily, or dry conditions. Commonly used in industries such as automotive, manufacturing, construction, assembly, and oil & gas, they provide reliable protection and enhanced performance for general maintenance tasks.

- Chemical and Oil Resistance5: Nitrile withstands petroleum-based oils, fuels, solvents, and acids without swelling or degrading.

- Durability (Abrasion & Puncture Resistance)6: Better than latex and vinyl, nitrile offers a longer service life in rough environments.

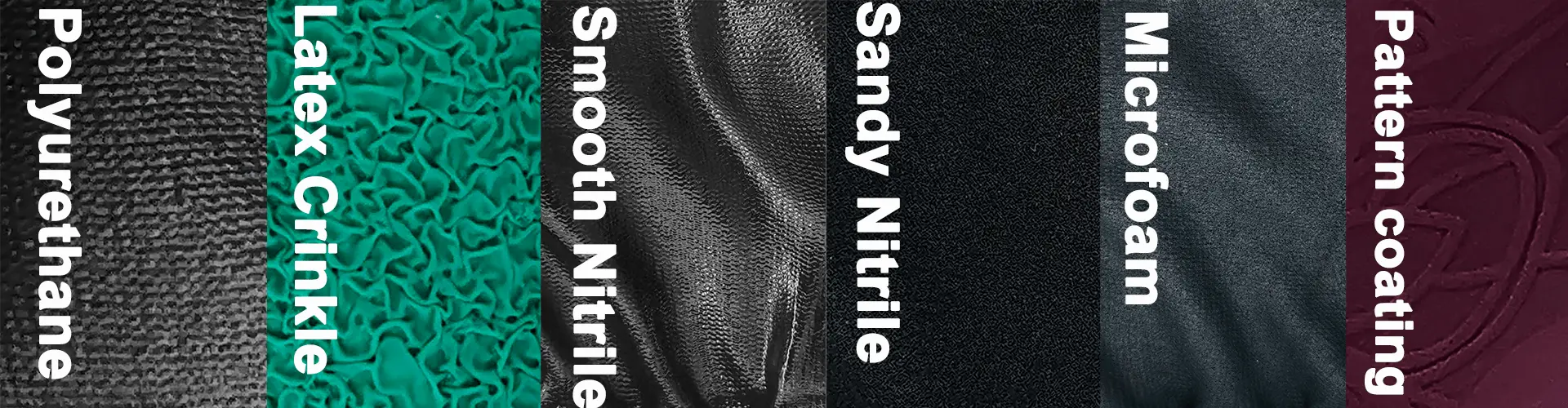

- Versatile Grip Options:

- Smooth Nitrile: Waterproof and ideal for dry conditions.

- Sandy Nitrile: Excellent grip in oily and wet conditions.

- Foam Nitrile: Flexible with a sponge-like grip, ideal for assembly.

- Microfoam Nitrile: Best grip across all conditions, highly breathable.

- Latex-Free7: Safe for individuals with latex allergies.

- Comfort and Dexterity: Thinner gauges and advanced liners provide flexibility and reduce hand fatigue.

| Feature | Description | Benefit for Buyer/User |

|---|---|---|

| Oil Resistance | Resists degradation from oils, fuels, greases | Longer glove life, better protection in oily environments |

| Abrasion Resist. | Withstands rubbing and friction | Increased durability, safety |

| Puncture Resist. | Resists penetration from sharp objects (nails, splinters) | Enhanced safety |

| Grip Variations | Smooth, Sandy, Foam, Microfoam for different conditions | Optimal performance for specific tasks |

| Latex-Free | No natural rubber latex proteins | Safe for allergic individuals |

| Dexterity | Thinner gauges (15g, 18g, 21g) allow fine motor skills | Improved productivity, less hand fatigue |

Nitrile vs. Latex Coated Gloves – Which is the Best For Your Workforce?

You need gloves, but the choice between nitrile and latex can be confusing. Making the wrong decision might expose workers to allergies or provide inadequate protection for the job.

Nitrile coated gloves are more durable, chemical-resistant, and allergy-safe, making them ideal for industrial applications. Latex coated gloves provide better elasticity and tactile sensitivity but have weaker oil resistance and can trigger allergies. For most industries, nitrile is the recommended choice.

- Material Composition:

- Nitrile: Synthetic, latex-free.

- Latex: Natural rubber, can cause allergies.

- Allergy Risk:

- Nitrile: No allergy risk.

- Latex: High allergy risk.

- Resistance Properties:

- Nitrile: Resists oils, chemicals, punctures.

- Latex: Good against water-based chemicals but poor oil resistance.

- Durability:

- Nitrile: Excellent, long-lasting.

- Latex: Degrades with oil/UV exposure.

- Elasticity and Fit:

- Nitrile: Good elasticity and fit.

- Latex: Superior elasticity and tactile sensitivity.

- Cost:

- Nitrile: Competitive, longer lifespan.

- Latex: Cheaper upfront, higher long-term risks.

Summary Table: Nitrile vs. Latex

| Feature | Nitrile Coated | Latex Coated | Advantage Highlighted |

|---|---|---|---|

| Allergy Safety | Excellent (Latex-Free) | Poor (Contains Latex Proteins) | Nitrile |

| Oil Resistance | Excellent | Poor | Nitrile |

| Chemical Resist. | Good to Excellent (Varies) | Fair to Good (Water-based) | Nitrile (Broader range) |

| Puncture Resist. | Excellent | Good | Nitrile |

| Abrasion Resist. | Excellent | Good | Nitrile |

| Elasticity | Good | Excellent | Latex |

| Tactile Sense | Good to Very Good | Excellent | Latex |

| Durability | Very Good | Good (Reduced by oils/UV) | Nitrile |

| Typical Cost | Competitive / Good Value | Potentially Lower Upfront | Varies / Nitrile often better value |

For most industrial buyers supplying workers in manufacturing, automotive, construction, or similar fields, nitrile coated gloves represent the safer and often more durable choice. Nitrile’s excellent chemical/oil resistance, high durability, and allergy safety make them versatile and reliable. At BullSafety, we focus on nitrile because we believe it offers the best balance of protection, durability, and safety for the industries our partners serve.

Conclusion

Nitrile coated gloves provide exceptional durability, resistance, and grip versatility. They are a reliable, cost-effective, and allergy-safe choice for numerous industries, protecting workers effectively in demanding environments.

-

Discover why oil grip is crucial for mechanics and how it can prevent accidents and improve efficiency on the job. ↩

-

Learn how abrasion resistance in gloves can significantly enhance worker safety and productivity in demanding environments. ↩

-

Discover how nitrile gloves provide essential protection against petrochemicals, enhancing safety for workers in the oil and gas sector. ↩

-

Learn why durability is crucial for gloves used in tough environments like construction and logistics, ensuring safety and efficiency. ↩

-

Understanding the benefits of chemical and oil resistance in nitrile gloves can help you choose the right protection for your needs. ↩

-

Explore how nitrile gloves outperform others in durability, ensuring long-lasting protection in tough environments. ↩

-

Learn why latex-free options are crucial for those with allergies, ensuring safety and comfort in various applications. ↩