As a man who has worked with protective gloves for years, I know how important it is to choose the right level of cut resistance. Understanding these levels can mean the difference between safety and injury on the job.

Cut-resistant levels, determined by EU and ANSI standards, classify gloves based on their ability to withstand cuts, helping workers select the right protection for their tasks.

In this guide, I’ll explain EN388 and ANSI cut-resistant levels, their use in Canada, and OSHA requirements for workplace safety.

What Are EU Cut-Resistant Levels?

The European Union (EU) classifies cut-resistant gloves using the EN388 standard. This system helps workers choose gloves that provide adequate protection against sharp objects.

EU cut-resistant levels range from 1 to 5, with higher numbers offering better cut protection.

How EN388 Levels Are Measured

The EN388 standard uses the "Coupe Test" to determine cut resistance. A rotating circular blade applies force to the glove material, and the number of cycles before cutting through the fabric determines the glove’s rating.

| Level | Blade Cycles (Coupe Test) | Cut Resistance (N) | Common Uses |

|---|---|---|---|

| 1 | 1.2 to 2.4 | Low | Light handling, general work |

| 2 | 2.5 to 5.0 | Moderate | Packaging, light assembly |

| 3 | 5.1 to 10.0 | High | Automotive, manufacturing |

| 4 | 10.1 to 15.0 | Very High | Metal handling, construction |

| 5 | 15.1+ | Maximum | Heavy-duty cutting tasks |

Limitations of EN388

From my experience, the EN388 test isn’t always the best measure of real-world performance.

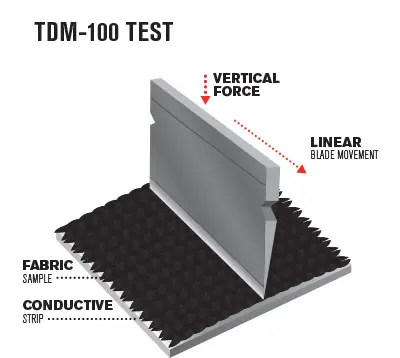

- Coupe Test vs. TDM Test: Some materials, like serrated blades, may not be accurately measured by the Coupe Test. That’s why the ISO 13997 (TDM test) is often used to measure cut resistance under higher force.

- Material Degradation: Over time, gloves lose effectiveness due to wear, washing, and environmental exposure.

What Are ANSI Cut-Resistant Levels?

In North America, the American National Standards Institute (ANSI) uses a different system to classify gloves. The ANSI/ISEA 105 standard tests how much force (in grams) is required to cut through a glove using a straight blade.

ANSI cut levels range from A1 to A9, with A9 offering the highest protection.

ANSI Cut Level Ratings

| Level | Force (grams) | Protection Level | Common Applications |

|---|---|---|---|

| A1 | 200-499 | Low | Light packaging, general tasks |

| A2 | 500-999 | Moderate | Assembly, warehouse work |

| A3 | 1,000-1,499 | High | Automotive, glass handling |

| A4 | 1,500-2,199 | Very High | Metal stamping, sharp tools |

| A5 | 2,200-2,999 | Superior | Heavy manufacturing |

| A6 | 3,000-3,999 | Exceptional | Steel cutting, high-risk jobs |

| A7 | 4,000-4,999 | Extreme | Industrial glass, mining |

| A8 | 5,000-5,999 | Maximum | Precision metalwork |

| A9 | 6,000+ | Ultimate | Extreme cutting environments |

ANSI vs. EN388: What’s the Difference?

I often get asked how ANSI and EN388 compare. Here’s a quick breakdown:

| Feature | ANSI | EN388 |

|---|---|---|

| Testing Method | Measures cutting force | Measures blade cycles |

| Cut Levels | A1 to A9 | Levels 1 to 5 |

| Best For | Real-world applications | Mechanical hazard testing |

From my perspective, ANSI ratings provide more accurate real-world data because they measure actual cutting force rather than cycles.

Are ANSI Cut-Resistant Levels Used in Canada?

Since Canada aligns many of its safety standards with the U.S., ANSI cut-resistant levels are widely accepted.

Yes, ANSI cut-resistant levels are recognized in Canada and comply with workplace safety standards.

Why ANSI Works in Canada

- Consistency with CSA Standards: The Canadian Standards Association (CSA) often incorporates ANSI testing methods.

- Regulatory Compliance: Manufacturing, mining, and construction industries in Canada use ANSI-rated gloves.

- Global Trade: Many Canadian companies source ANSI-compliant gloves from international manufacturers.

Common ANSI-Level Gloves in Canada

| Industry | Hazards | ANSI Levels Used |

|---|---|---|

| Construction | Glass, sharp tools | A4 to A6 |

| Manufacturing | Metals, heavy machinery | A5 to A7 |

| Mining | Abrasive materials, tools | A6 to A9 |

From what I’ve seen, most businesses in Canada prefer ANSI-rated gloves for high-risk work environments.

Does OSHA Require Cut-Resistant Gloves?

The Occupational Safety and Health Administration (OSHA) focuses on workplace safety but doesn’t mandate specific gloves.

OSHA requires employers to assess workplace hazards and provide appropriate PPE, including cut-resistant gloves when necessary.

OSHA’s Hand Protection Guidelines

- Hazard Assessment: Employers must evaluate risks like sharp tools, machinery, and abrasives.

- Proper PPE Selection: Gloves should match the level of risk. ANSI and EN388 gloves are commonly used.

- Employee Training: Workers must learn how to use and maintain gloves properly.

OSHA Compliance Examples

| Industry | Common Hazards | Recommended Gloves |

|---|---|---|

| Metalworking | Sharp edges, high impact | ANSI A4 or higher |

| Construction | Glass, metal, tools | EN388 Level 4 or ANSI A5 |

| Food Processing | Blades, sharp objects | ANSI A3 to A5, food-safe materials |

From my experience, businesses that follow OSHA’s guidelines reduce injuries and maintain compliance without unnecessary expenses.

Conclusion

Understanding ANSI and EN388 cut-resistant levels helps workers select the right gloves for their job. In North America, ANSI-rated gloves are commonly used, while EN388 is the standard in Europe. Choosing the right protection ensures safety, compliance, and efficiency in any workplace.