Finding reliable cut-resistant glove suppliers in Spain is tough. You might waste time vetting factories that don’t meet your quality standards, hurting your business and reputation.

Spain has top-tier cut-resistant glove makers like Delta Plus España, Juba, and Tomás Bodero. They offer EN388-certified gloves that provide excellent quality and value for PPE wholesalers.

Top Spanish Cut-Resistant Glove Factories.

I have spent years visiting factories, not just in Spain but around the world. As a manufacturer myself with my company, BullSafety, I know exactly what to look for when it comes to quality, materials, and production. After many trips to Spain, I’ve compiled this list of the top 10 manufacturers. These facilities mix European quality with good pricing. They are great partners for PPE wholesalers who need reliable suppliers in the Mediterranean. This list will save you time and help you find a partner you can trust.

Is Delta Plus España the Leading Cut-Resistant Glove Producer in Spain?

It’s hard to find manufacturers with a long, proven history. You might overlook established names, thinking they are too big or expensive, and miss a great opportunity.

Yes, Delta Plus España is a major player. Based in Alicante since 1986 and part of a global group, they produce high-quality, EN388:2016 certified cut-resistant gloves for wholesalers worldwide.

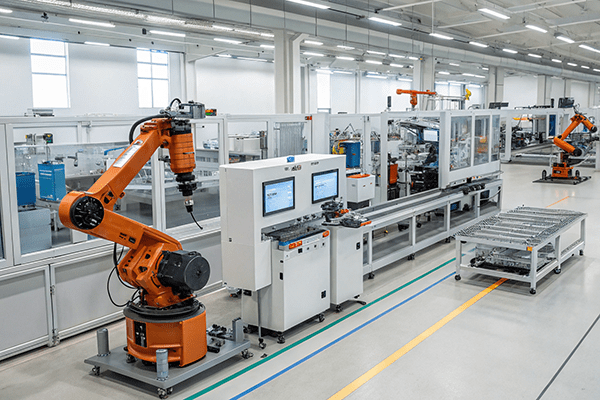

Delta Plus España manufacturing facility.

When I visited their Alicante facility, I saw how they represent one of Spain’s most established PPE makers. They are part of the French Delta Plus Group, which started in 1977, so their team has over 35 years of local market knowledge. The company holds ISO 90011, ISO 14001, and OHSAS 18001 certifications. This ensures steady quality across all their products. Their cut-resistant gloves2 range from A1 to A5 cut levels. They use modern materials like HPPE fibers and special coatings. They produce for both private labels and their own Delta Plus brand, serving wholesalers across Europe, North Africa, and Latin America. With a capacity of over 5 million pairs a year, they get good prices because they make so much. This lets them keep strict European quality standards while staying competitive.

| Feature | Details |

|---|---|

| Location | Alicante, Spain |

| Experience | 35+ years (part of Delta Plus Group) |

| Certifications | ISO 9001, ISO 14001, OHSAS 18001 |

| Product Range | Cut levels A1-A5, HPPE & advanced coatings |

| Annual Capacity | Over 5 million pairs |

Does Juba Personal Protective Equipment Offer Comprehensive Cut-Protection Solutions?

Finding Spanish factories that only make hand protection is hard. Most places produce many types of PPE and don’t have deep glove expertise.

Juba Personal Protective Equipment has specialized in protective gloves since 1950. Their large cut-resistant lines are all certified to the newest European standards.

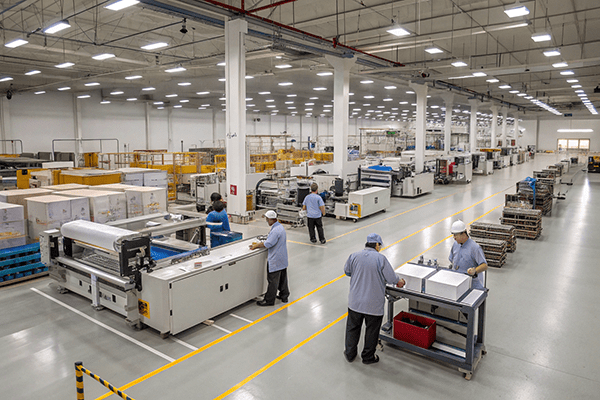

Juba protective gloves manufacturing.

Website:https://www.jubappe.com/

Juba3 really impressed me because they are Spain’s oldest dedicated glove maker. Their 70-year history means they have unmatched expertise in hand protection. The company runs three factories in Spain and employs over 400 people who only make gloves. Their cut-resistant line includes 25 different models, from basic cut level 1 to advanced level 5 protection. I learned that Juba was one of the first in Spain to use Dyneema®4 and other high-performance fibers in their gloves. They even have their own testing lab, which is certified by ENAC (the Spanish National Accreditation Entity). This lets them develop new products and check quality very quickly. They export to over 60 countries and are very strong in the construction, auto, and metal industries. Their OEM service is great for wholesalers, offering custom branding, packaging, and even new material development for specific jobs.

Why Choose Tomás Bodero S.A. for Industrial Cut-Resistant Gloves?

Industrial jobs need gloves that can handle more than just cuts. Standard products often break down in tough, heavy-duty situations.

Tomás Bodero S.A. from Barcelona makes heavy-duty cut-resistant gloves. They combine cut safety with features like heat resistance, chemical protection, and better grip.

Tomás Bodero industrial gloves production.

Website:https://www.directindustry.com/

Tomás Bodero S.A.5 has found its specialty in industrial protection since 1965. Their factory in Barcelona focuses on engineered solutions for tough work areas. I was interested to see their special coating technologies that make gloves more cut-resistant while keeping them flexible and easy to grip. Their "MaxiCut6" series is a good example. It combines cut level 4 protection with heat resistance up to 100°C, which is perfect for the metalworking industry. They use modern automated knitting machines from Shima Seiki. This ensures every glove is high quality. The factory uses over 20 different liner materials, including recycled fibers to support sustainability. They check every single glove for quality. They can also do small orders starting at 1,000 pairs, which is great for wholesalers who want to test new markets.

How Does Iturri Group Excel in Government and Military Contracts?

Selling to the government requires many certifications and a reliable supply chain. Many factories can’t handle the paperwork for public sector sales.

Iturri Group in Seville specializes in certified PPE for government contracts. They have NATO supplier codes and make cut-resistant gloves for military and emergency services.

Iturri Group PPE manufacturing facility

Website:https://www.iturri.com/

Iturri Group7 uses its 70 years of experience supplying Spanish government agencies. Their main office in Seville has advanced manufacturing for tactical and emergency response gloves. What sets them apart is their AQAP 2110 certification8 for NATO supplies. This allows them to get military contracts all over Europe. Their tactical gloves use Kevlar® and other aramid fibers. This gives them cut level 5 protection but also the dexterity needed to handle weapons. Their production follows very strict rules for tracking, which government contracts require. They keep extra stock on hand to make sure critical services never run out of supplies. Iturri also makes uniforms, so they can offer complete PPE packages that are attractive to large government buyers. They provide all the needed documents, like CE certificates and test reports, which is essential for winning public bids.

Which Barcelona Manufacturer Leads in Innovative Coating Technologies?

Old coating methods don’t work well in wet conditions. Workers need a good grip even when things are wet or oily.

Guantes Industriales Catalans (GIC) in Barcelona developed a special micro-foam nitrile coating. It gives amazing wet grip while still meeting EN388 cut-resistance standards.

GIC coating technology laboratory.

GIC is a center of innovation in Barcelona for protective glove technology. It was started in 1982 by former chemical engineers, so they focus on improving coating chemistry. Their patented "[AquaGrip9]" technology is very impressive. It uses tiny nitrile structures that push liquids away from the glove surface. This technology keeps 90% of the dry grip performance even when the glove is completely wet. The coating process is very precise, using special temperature controls to create a consistent structure on every glove. Their lab tests show that these gloves last 40% longer than ones with standard nitrile coatings. As a smart business move, GIC offers exclusive sales rights for their technologies in certain areas. This protects wholesalers who invest in bringing these innovative products to their market. The facility also focuses on being green with zero liquid discharge and solvent recovery systems.

Does Valenciaga Safety Products Offer Competitive Pricing for Volume Orders?

Price is always a factor, forcing wholesalers to find a balance between quality and cost. Some of the best factories are too expensive for competitive markets.

Valenciaga Safety Products in Valencia uses efficient manufacturing and a great location. They offer cut-resistant gloves for 15-20% less than typical European prices.

Valenciaga Safety Products manufacturing line.

Valenciaga is smart about its location. Being in Valencia’s free trade zone10 helps them save money on imported raw materials while still being an EU manufacturer. From my tour, I saw they have invested a lot in automation. This lowers labor costs but keeps quality high. Their production lines run 24/7, which means they get the most out of their machines and can lower the cost per glove. They focus on making large amounts of the most common glove types, like cut levels 3 and 4. This covers about 80% of what the market needs. They offer discounts for large orders, starting at 10,000 pairs, and even better prices for yearly contracts. They keep their inventory low, so they can offer 4-week lead times instead of the usual 8-12 weeks. They never compromise on quality and have regular checks to prove it.

Why Consider Protección Laboral Mediterránea for Seasonal Production?

Demand can change with the seasons, creating problems with inventory. Fixed production schedules can leave wholesalers with too much stock or not enough.

Protección Laboral Mediterránea (PLM) in Alicante uses flexible manufacturing. This lets them handle seasonal changes and offer cut-resistant gloves with a 2-week rapid response.

PLM flexible manufacturing systems.

PLM has changed Spanish glove making with its flexible approach. Their factory in Alicante has cross-trained workers who can switch between different product lines very quickly. This allows them to increase or decrease production from 20% to 150% of their capacity in just a few days. This is perfect for seasonal products, like lightweight cut-resistant gloves11 needed for summer construction projects. They keep a stock of key materials, so they can respond to unexpected orders fast. Their "FastTrack12" program even guarantees 2-week delivery for certain designs. This is much faster than the industry standard of 6-8 weeks. Their factory has modular coating lines that can be changed for different glove styles. They even share their production schedules with key partners for better planning. You can order as few as 500 pairs, which is great for smaller wholesalers.

How Does Seguridad Industrial Vasca Address Heavy Industry Requirements?

Heavy industries like steel and automotive work need special protection. Normal gloves just don’t last when exposed to industrial lubricants and tough conditions.

Seguridad Industrial Vasca (SIV), in the industrial center of Bilbao, makes cut-resistant gloves for the steel, auto, and heavy machinery industries with extra durability.

SIV heavy industry glove testing.

SIV’s location in Spain’s industrial heartland helps them specialize in gloves for extreme-duty work. The company was founded by former steelworkers, so they know from experience that generic safety gloves are not good enough. Their cut-resistant products have multiple layers of protection. This includes puncture-resistant palms and longer cuffs to protect the forearm. The coatings they use do not break down when exposed to industrial oils, coolants, and solvents. What I found unique was their applications lab. Here, customers can test gloves in real work conditions. This teamwork has led to new ideas like built-in sweat-wicking liners and treatments that prevent bacteria growth for longer wear. They have equipment that can handle heavy-gauge materials, which is not common in most glove factories. Their ISO 45001 certification13 shows their commitment to worker health and safety.

Which Andalusian Manufacturer Excels in Agricultural Cut Protection?

Farm work has unique dangers that need special hand protection. Factories focused on cities often don’t understand the needs of rural markets.

Guantes Agrícolas de Andalucía (GAA) in Córdoba specializes in cut-resistant gloves for farm work. Their gloves include features like thorn resistance and pesticide safety.

GAA agricultural glove production.

GAA serves an important need for agricultural hand protection from its base in Córdoba. Since they are surrounded by Spain’s farming regions, they have a deep understanding of the dangers. Their cut-resistant gloves are made for specific jobs, like harvesting citrus fruits, where thorns and sharp branches are a big risk. They choose materials that can resist chemicals from pesticides while still being flexible. Their products include longer gauntlet styles to protect forearms during pruning. They even use seasonal colors to help workers know when it’s time to replace their gloves for safety. GAA works with farming cooperatives to offer good prices for large orders. A key part of their process is real-world field testing during harvest seasons. They also use natural rubber alternatives14 to help workers with latex allergies.

Does Manufactura de Guantes Técnicos Offer Private Label Excellence?

To build your own brand, you need a manufacturing partner you can trust with quality and privacy. Many factories don’t take private label work seriously.

Manufactura de Guantes Técnicos (MGT) near Madrid has a special division just for private labels. They make custom cut-resistant gloves with full confidentiality.

MGT private label production facility.

MGT has built its business around being great at private label work15. When I visited their facility near Madrid, I saw they have separate production areas to keep client designs from getting mixed up. Every private label client gets a dedicated project manager. This ensures clear communication and high-quality standards. The company protects brands with strict non-disclosure agreements and by controlling who can enter the factory. Their design services are extensive, including custom colors, logo placement, and unique packaging to make a wholesaler’s brand stand out. MGT has a large library of over 50 liner options and 20 coating types, allowing for truly unique products. They also provide full testing services and create technical documents with the client’s branding. They offer a good balance with minimum orders starting at 3,000 pairs for custom designs.

Conclusion

Spain provides great cut-resistant glove makers with European quality and good prices. For those seeking a direct manufacturing partner in Asia, my company, BullSafety, offers certified, cost-effective solutions.

-

Learn about ISO 9001 certification to see how it ensures quality management and enhances business credibility. ↩

-

Explore this link to understand the advantages of cut-resistant gloves, essential for safety in various industries. ↩

-

Discover Juba’s rich history, innovation in glove manufacturing, and why their expertise sets them apart in hand protection. ↩

-

Discover the benefits of Dyneema® in glove manufacturing and why it’s a game-changer for hand protection. ↩

-

Learn more about Tomás Bodero S.A.’s history, product range, and expertise in industrial protection to make informed purchasing decisions. ↩

-

Learn more about the MaxiCut series to understand its unique features and benefits for metalworking and industrial applications. ↩

-

Learn more about Iturri Group’s expertise in tactical gloves, PPE, and their role in supplying government and military contracts across Europe. ↩

-

Understanding AQAP 2110 certification can help you grasp its significance in securing military contracts and ensuring quality in defense supplies. ↩

-

Explore how AquaGrip technology enhances grip and durability in wet conditions, revolutionizing glove performance. ↩

-

Exploring this link will provide insights into how free trade zones can significantly reduce costs and enhance manufacturing efficiency. ↩

-

Discover the applications and benefits of lightweight cut-resistant gloves, essential for safety in summer construction projects. ↩

-

Explore how the FastTrack program revolutionizes delivery times in the glove industry, ensuring rapid response to customer needs. ↩

-

Learn about ISO 45001 certification to see how it ensures health and safety standards in the workplace, benefiting both workers and employers. ↩

-

Discover the advantages of natural rubber alternatives, especially for those with latex allergies, ensuring safer work conditions. ↩

-

Understanding private label work can help you leverage branding opportunities and enhance your business strategy. ↩