Working in the cold is tough, but the wrong gloves make it dangerous. They are either too bulky to work with or not warm enough, leaving your hands numb.

The best winter work glove is a careful balance of thermal insulation1, flexibility for the task, and durability for the environment2. This means there is no single "best" glove; the right choice always depends on the specific job requirements, from the materials used to the overall fit.

Winter Work Gloves for Different Jobs.

Finding this perfect balance is the biggest challenge we face in glove manufacturing3. After more than ten years at BullSafety, I’ve learned that every feature you add affects another. More warmth can mean less flexibility. More durability can add weight. As a specialty manufacturer for PPE wholesalers4, our entire process is built around helping our partners navigate these trade-offs. Let’s break down the key factors so you can make the best choice for your customers.

How Do You Choose Between Down and Synthetic Insulation Materials?

Confused by all the different insulation types on the market? Choosing the wrong one can leave your hands either cold or clammy, completely defeating the purpose of the glove.

For most work applications, synthetic insulations5 like Thinsulate are the superior choice. They keep your hands warm even when damp from sweat or snow, are less bulky, and provide the dexterity needed for handling tools and materials safely. This is a key finding from our internal testing.

Synthetic Glove Insulation Texture.

The main job of insulation is to trap a layer of air around your hands to keep them warm. How it does this matters a lot. While natural down is an excellent insulator in dry conditions, it loses its warming ability when it gets wet. In the real world of work, hands get sweaty. That’s a problem.Points out that high-intensity work can cause sweating, which actually makes hands colder if the insulation can’t handle moisture. This is where synthetics shine. Materials like Thinsulate are specifically designed to be thin and flexible, which boosts your ability to grip and handle objects.Notes that its moisture-wicking properties6 keep hands dry. From my experience developing gloves, this is critical. We often create solutions for logistics companies where workers are moving constantly. A bulky, non-wicking glove is a productivity killer.

Here is a simple breakdown we use at BullSafety when consulting with our partners:

| Insulation Type | Pros | Cons | Best For |

|---|---|---|---|

| Natural Down | Excellent warmth-to-weight ratio (when dry) | Loses insulating power when wet; bulky | Low-intensity, very cold and dry conditions |

| Standard Synthetics | Water-resistant, affordable | Can be bulky | General purpose, moderate cold |

| Thinsulate | Very warm for its low thickness, flexible | Higher cost | Tasks needing high dexterity in the cold |

| PrimaLoft | Excellent water resistance, soft, compressible | Higher cost | Wet conditions, mimicking down’s feel |

How Can You Maintain Grip and Dexterity in Freezing Conditions?

Are you or your workers constantly dropping tools because of stiff, bulky gloves? Losing that hand function is not just frustrating; it’s a serious safety risk on any job site.

The key to maintaining grip and dexterity is choosing gloves made with flexible outer materials7 and a smart, low-profile insulation strategy. Look for features like synthetic leather palms8, silicone grip patterns, and pre-curved finger designs that mimic the hand’s natural resting state.

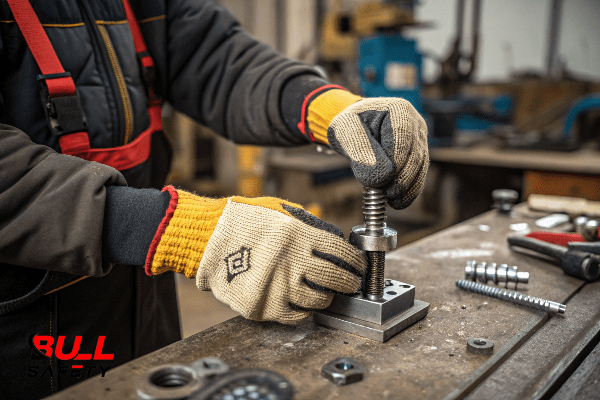

Dexterity with Winter Gloves.

When your hands are exposed to the cold, they lose their sensitivity and strength. As rightly states, this can be dangerous when a task requires you to handle tools or operate machinery. This is the central engineering puzzle we work on at BullSafety: how do we pack in warmth without sacrificing the dexterity needed to perform a job safely? For a construction client, we can’t just provide a warm glove; we have to provide a warm glove9 that still allows a worker to feel and securely grip rebar or a hammer. This requires a multi-faceted approach. We use advanced, thin insulations that provide warmth without the bulk10.Confirms that lightweight options are best for tasks that demand dexterity. The outer shell material is just as important. We often use high-quality synthetic leather or add nitrile coatings11 to the palm and fingers. These materials resist stiffening in the cold and provide a much better grip than traditional leather.

What’s the Right Balance Between Waterproofing and Breathability?

Do your hands end up wet one way or another, either from snow soaking through or from your own sweat building up inside? It can feel like an impossible choice to make.

The ideal solution is a glove constructed with a waterproof and breathable membrane. This acts as a barrier that stops outside moisture from getting in while allowing sweat vapor to escape, keeping your hands completely dry.

Here’s a fact that drives our design process: wet hands lose heat up to 25 times faster than dry hands. Therefore, keeping hands dry is just as important as insulating them. The problem is, a fully "waterproof" glove made of a non-breathable material like rubber will trap sweat. As you work and your body heats up, that trapped moisture will eventually make your hands cold and clammy. This is a point also highlighted in search results, which mention moisture-wicking linings12 are important to keep hands dry even when you sweat.A common request I get from our wholesale partners is for a 100% waterproof glove. My first question is always, "What is the activity level of the person wearing it?" For a worker doing something labor-intensive, breathability is not a luxury; it’s a necessity for safety and comfort. This is where modern glove technology comes in. We insert microporous membrane linings13 between the outer shell and the insulation. These membranes have pores small enough to block large water droplets but large enough to let small water vapor (sweat) molecules out.

Why are Sizing and Fit Essential for Winter Glove Performance?

Have you ever found gloves in your "size" that just don’t feel right? A poor fit isn’t just a minor annoyance; it seriously undermines both the warmth and the safety of any winter glove.

A correct fit is absolutely essential for performance. If a glove is too tight, it will restrict blood flow and compress the insulation, making your hands colder. If it’s too loose, it reduces your dexterity and creates air gaps that let cold air in.

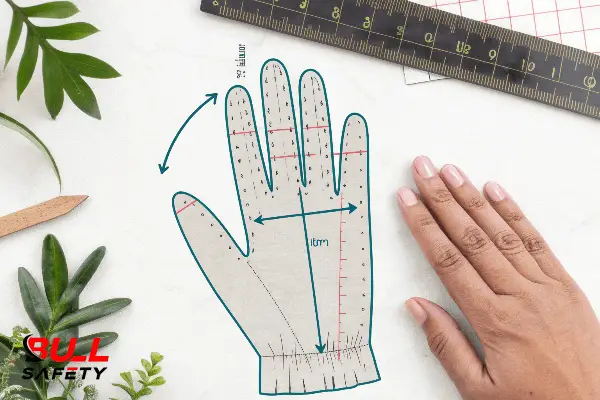

How to Measure for Gloves.

As a manufacturer, we design gloves based on precise measurements, but those designs only work if the user wears the right size. Here’s why it’s so critical. First, insulation works by trapping air. If you wear a glove that’s too tight, it squeezes all of that trapped air out, destroying the glove’s ability to keep you warm. You could have the most advanced insulation in the world, but it would be useless. A tight fit also restricts circulation to your fingers, which is another reason they might feel cold. On the other hand, a glove that’s too big is clumsy. The extra material at the fingertips gets in the way of picking things up, and the entire glove can feel sloppy, reducing your control and creating a potential snag hazard around machinery. It also creates empty space inside the glove, allowing cold air to circulate and nullify the insulation’s effect. For our wholesale partners, we provide detailed sizing charts14 and always recommend they train their sales teams to educate customers on how to measure their hands properly. It’s a simple step that ensures the glove performs as designed.

Conclusion

Choosing the right winter glove means balancing insulation, dexterity, weather resistance, and fit. Understanding these factors helps you make an informed decision and truly protect your team on the job.

-

Explore this link to understand how thermal insulation materials enhance glove performance in cold conditions. ↩

-

Learn why durability is crucial for winter work gloves and how it impacts their longevity and effectiveness. ↩

-

Explore this link to understand the complexities and innovations in glove manufacturing, enhancing your knowledge in the field. ↩

-

This resource will provide insights into the selection process for PPE wholesalers, crucial for making informed decisions. ↩

-

Explore this link to understand why synthetic insulations are preferred for warmth and dexterity in work environments. ↩

-

Explore how moisture-wicking properties enhance comfort and performance in gloves, especially for active workers. ↩

-

Discover how flexible outer materials enhance grip and comfort in gloves, making them ideal for various activities. ↩

-

Learn about the advantages of synthetic leather palms in gloves, including durability and improved grip. ↩

-

Explore this link to discover warm gloves designed for optimal dexterity and grip, ensuring safety in cold conditions. ↩

-

Discover how advanced materials and insulation technologies can keep your hands warm while maintaining dexterity, crucial for safety and performance in cold environments. ↩

-

Learn how nitrile coatings enhance glove performance, offering superior grip and flexibility for tasks requiring dexterity, especially in cold environments. ↩

-

Explore this link to understand how moisture-wicking linings can keep your hands dry and comfortable during activities. ↩

-

Discover the advantages of microporous membrane linings in gloves for optimal breathability and waterproofing. ↩

-

Exploring effective sizing chart practices can help users select the perfect fit, maximizing insulation and functionality. ↩