Choosing the wrong winter gloves can leave your hands dangerously cold or make your work impossible. You need protection, but you also need to get the job done. How do you pick the right pair?

The best Wells Lamont winter glove1 depends entirely on your needs. For extreme cold, the heavily insulated 78782 is superior. For tasks requiring precision, the 7794 excels. The 526N offers a balanced solution for general-purpose work in moderately cold weather, making it a versatile choice.

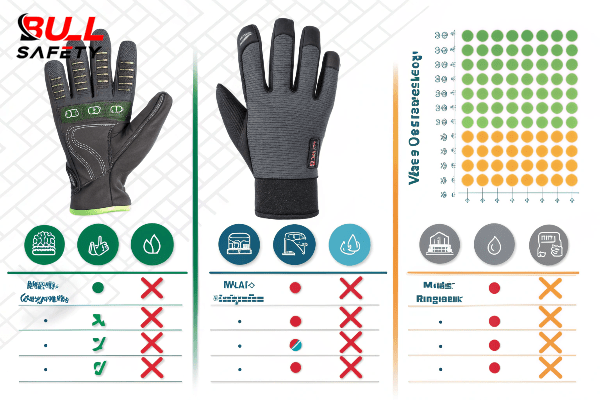

Wells Lamont Winter Glove Comparison.

As a glove manufacturer, I’ve seen countless customers struggle with this decision. It reinforces a lesson I learned long ago: there is no single "best" glove for everyone. Every worker faces a unique balance between warmth, flexibility, and durability3 based on their specific job. The key is understanding the materials and design4 to find the perfect match for your hands and your work. Let’s break down these models to help you find yours.

Model 526N vs 7878 vs 7794: Key Features and Specifications Breakdown?

Facing a wall of technical specifications can be overwhelming. Words like "Thinsulate," "goatskin," and "nitrile coating" are meaningless if you don’t know how they impact performance. You just want to know which glove works.

The 7878 is built for maximum warmth5 with a thick lining and waterproof barrier. The 7794 prioritizes dexterity, using a flexible shell and lighter insulation for better finger movement6. The 526N strikes a balance between the two, offering solid warmth and good durability for everyday use.

Glove Model Feature Comparison.

From my experience in glove production, the spec sheet tells the most important story. It’s where a glove’s purpose is truly defined. I’ve spent years helping clients decipher these details to find the right glove for their workforce. Let’s look at what makes these gloves different. A direct comparison helps clear up the confusion and points you to the right choice. Here’s how these three popular models stack up against each other based on their core components.

| Feature | Model 526N | Model 7878 | Model 7794 |

|---|---|---|---|

| Primary Use | General Purpose, Construction | Extreme Cold, Low-Dexterity Tasks | High Dexterity, Cool Conditions |

| Insulation | 100g 3M Thinsulate™ | 200g 3M Thinsulate™ + Foam | 50g 3M Thinsulate™ |

| Outer Material | Cowhide Leather | Leather Palm, Synthetic Shell | Hi-Vis Synthetic Shell |

| Palm Material | Reinforced Cowhide | Goatskin Palm | Sandy Nitrile Coated Palm |

| Waterproofing | Water-Resistant | Fully Waterproof Liner | Water-Resistant |

| Key Feature | Durability and Value | Maximum Warmth | Superior Grip and Flexibility |

This table shows that your work environment is the biggest factor. Are you handling frozen materials or working in a blizzard? The 7878 is your glove. Are you wiring or handling small components? The 7794 is the clear winner. For everything in between, the 526N is a reliable workhorse.

Warmth and Insulation Performance: Which Model Handles Extreme Cold Best?

You’re working outside, and the temperature is dropping fast. Your gloves aren’t cutting it, and your fingers are starting to go numb. This isn’t just uncomfortable; it’s a serious safety risk.

For handling extreme cold, the Model 7878 is the undisputed champion. It features heavy-duty insulation7, often combining Thinsulate™ and foam, along with a waterproof liner8 to keep hands warm and dry in the harshest winter conditions, just as described by Wells Lamont Industrial.

Glove Insulation Technology.

In my factory, we often talk about insulation in terms of "grams per square meter9." It’s a precise measurement that tells you how much warmth a glove can provide. A glove with 50g insulation is great for a cool autumn day, but for sub-zero work, you need something much heavier. The Model 7878, with its 200g Thinsulate™10 and additional foam lining, is designed for exactly those conditions. Thinsulate™ works by trapping air molecules between your hands and the outside cold, creating a thermal barrier. The denser the fibers (higher gram count), the more air it traps. The 7878 also includes a waterproof liner, which is critical. Wet hands lose heat 25 times faster than dry hands, so staying dry is just as important as staying warm. The trade-off is dexterity. A glove this thick won’t let you handle tiny screws, but it will keep your hands safe and functional when warmth is the top priority.

Durability and Grip Analysis: Long-term Performance Comparison?

You’ve found a warm pair of gloves, but after a few weeks of tough work, they’re already falling apart. The seams are splitting and the palms are worn through. Now you have to buy another pair.

The Model 526N, with its reinforced cowhide leather palm11, offers the best long-term durability for general use. For superior grip, especially in wet or oily conditions, the Model 7794’s sandy nitrile coated palm12 provides unmatched performance, much like the latex palm coatings mentioned by Wells Lamont Industrial.

Durable Work Glove Grip.

I’ve seen firsthand how different materials hold up in the field. Leather, especially cowhide like in the 526N, has been a go-to for durability for over a century for good reason. It naturally resists abrasion and punctures. When you add reinforcement to high-wear areas like the palm and fingertips, you create a glove that lasts. On the other hand, grip is a different science. The 7794 uses a sandy nitrile coating. We apply this coating in our own factory by dipping a liner into liquid nitrile mixed with an abrasive agent. This creates a rough, sandpaper-like texture that channels away liquids and bites into surfaces, providing an excellent grip. The 7878 uses goatskin, a favorite for its high natural lanolin content, which keeps it soft and flexible even in the cold, but it trades some of the raw toughness of cowhide for better feel.

Price vs Value: Finding the Best Wells Lamont Winter Glove for Your Budget?

You need high-quality gloves but have a strict budget to follow. It’s tempting to grab the cheapest option, but you worry it won’t last, costing you more in the long run.

The Model 526N typically offers the best overall value, balancing a moderate price with excellent durability for a longer lifespan. While the 7794 and 7878 may have higher initial costs, their specialized features provide superior value if your work absolutely demands high dexterity or extreme warmth.

As someone who oversees the entire glove manufacturing process, from sourcing raw materials to final stitching, I have a deep understanding of what drives cost. The 7878 is the most expensive because it’s packed with technology: high-gram Thinsulate™13, a multi-layer construction14, and a full waterproof membrane15. These materials and complex production steps add up. The 7794’s cost comes from its specialized nitrile coating and hi-vis synthetic shell. The 526N, made with sturdy cowhide, is often the most cost-effective to produce at scale, which is why it hits that sweet spot of value. When advising procurement managers, I always tell them to think about the "cost per use." A $15 glove that lasts a month is more expensive than a $25 glove that lasts three months. The 526N embodies this principle, making it a smart investment for most businesses.

Conclusion

Choosing the right Wells Lamont winter glove isn’t about finding one perfect model. It’s about matching the glove’s specific strengths—warmth, dexterity, or durability—to the unique demands of your work and budget.

-

Explore this link to discover the top Wells Lamont winter gloves tailored for extreme cold conditions. ↩

-

Learn why the heavily insulated 7878 is considered the best choice for extreme cold weather. ↩

-

Understanding these factors is crucial for selecting the right gloves for your specific needs. ↩

-

Exploring this will help you make informed choices about glove selection based on your work requirements. ↩

-

Explore this link to discover top-rated winter gear designed for ultimate warmth, ensuring you stay cozy in the cold. ↩

-

Check out this resource for tips on selecting gloves that enhance finger movement while keeping your hands warm. ↩

-

Explore this link to understand how heavy-duty insulation can enhance your winter gear’s performance and comfort. ↩

-

Discover the advantages of waterproof liners in gloves to keep your hands warm and dry during extreme cold. ↩

-

Understanding this measurement is crucial for selecting the right insulation for your needs, ensuring optimal warmth and comfort. ↩

-

Exploring the advantages of 200g Thinsulate™ can help you make informed decisions about insulation for extreme conditions. ↩

-

Explore this link to understand how reinforced cowhide leather enhances durability and performance in gloves. ↩

-

Discover the advantages of sandy nitrile coatings for better grip and safety in challenging environments. ↩

-

Exploring the advantages of high-gram Thinsulate™ can reveal how it enhances glove performance and comfort, crucial for informed choices. ↩

-

Understanding multi-layer construction helps you see how advanced glove designs improve durability, protection, and performance, justifying higher costs. ↩

-

Understanding how a full waterproof membrane functions in gloves helps you choose products that offer superior protection and durability in wet conditions. ↩